单梁桥式起重机的设计

1.无需注册登录,支付后按照提示操作即可获取该资料.

2.资料以网页介绍的为准,下载后不会有水印.资料仅供学习参考之用.

密 惠 保

[来源:http://www.think58.com]

单梁桥式起重机的设计(含毕业论文说明书23000字,开题报告,文献翻译,中期检查报告,cad图纸6张)

摘 要

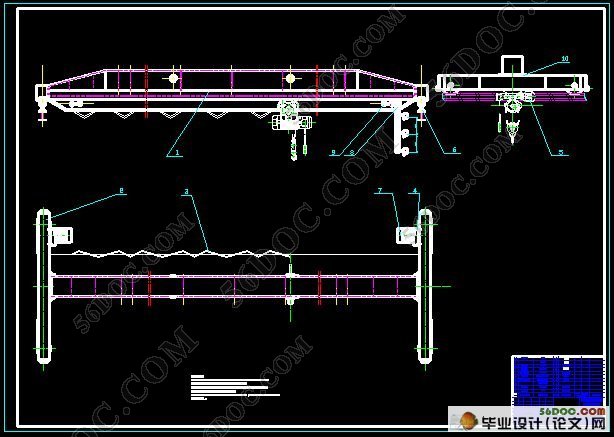

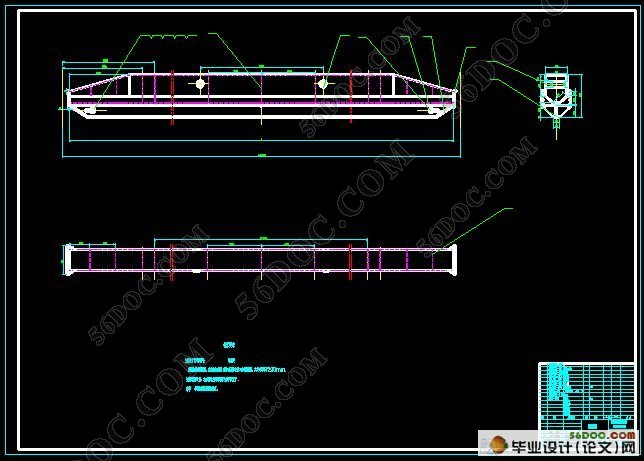

我做的毕业设计课题是单梁桥式起重机设计。单梁桥式起重机是一种轻型起重设备,它适用起重量为1~20 吨,适用跨度4.5~16.5米,工作环境温度在≥-35。C与≤+35。C范围内,适合于车间、仓库、露天堆场等处的物品装卸工作。桥架由一根主梁和两根端梁刚接组成。根据起重量和跨度,主梁采用普通工字钢和U形槽组合焊接形成。主梁和端梁之间采用承载突缘普通螺栓法兰连接。提升机构采用CD型电葫芦。

此次设计的主要内容有:问题的提出、总体方案的构思,结构设计及对未知问题的探索和解决方案的初步设计,装配图、零件图等一系列图纸的设计与绘制,以及毕业设计说明书的完成。

关键词 :起重机;桥式起重机;大车运行机构;小车运行结构;小车起升;结构桥架;主端梁 。

ABSTRACT

The topic of my graduation design is list the beam bridge type derrick of design the list beam bridge type derrick is a kind of light heavy equipments, it start to apply the weight as 1~20 tons, apply to across degree 4.5~16.5 meters, the work environment temperature is in the ≥ -35.C and ≤ +35.Inside scope, suitable for car, warehouse, open-air heap field etc. of the product pack to unload a work. The bridge was carried beam by a lord beam and 2 to just connect to constitute. According to weight with across a degree, lord beam adoption common the work word steel and U form slot combination weld formation. Lord beam and carry an of beam an adoption loading To good luck common stud bolt method orchid conjunction. Promote the organization adoption CD type an electricity bottle gourd.

[资料来源:THINK58.com]

The main contents of this time design have: The problem put forward, conceive outline of total project, possibility design, structure design and draw towards doing not know a problem of investigate and solution of first step design, assemble diagram, spare parts diagram wait a series the design of the diagram paper with, end include graduation design manual of completion.

Keywords: cranes;bridge type derrick ; During operation organization; Car running structure; Car hoisting structure; Bridge; Main girders.

工作条件及设计要求

为机修车间设计一台LD型电动单梁桥式起重机,具体要求如下:

⑴起重量:5吨

⑵起升高度:9米

⑶电动葫芦运行速度:30m/min

⑷电动葫芦的起升速度:8 m/min

⑸葫芦最大轮压:Pmax=1900公斤(kg)

⑹葫芦自重:G=500kg

⑺起重机跨度:16.5 m

⑻大车运行速度:45m/min

⑼大车轮距:2.5m

[来源:http://think58.com]

⑽工作级别:M5

⑾工作环境:一般常温

⑿使用寿命:10年

⒀操纵室操纵:G操=400公斤

[资料来源:http://www.THINK58.com]

上一篇:尾参脱须机设计

下一篇:闭锁式液力偶合器的设计