汽车驱动桥桥壳的强度分析(有限元分析ANSYS)★

1.无需注册登录,支付后按照提示操作即可获取该资料.

2.资料以网页介绍的为准,下载后不会有水印.资料仅供学习参考之用.

密 惠 保

[资料来源:http://think58.com]

驱动桥桥壳的强度分析(有限元分析ANSYS)★(开题报告,答辩ppt,论文说明书33000字)

摘要

由于汽车的行驶工况比较复杂,驱动桥桥壳的强度和动态性能直接影响汽车运行安全,合理地设计桥壳也是提高汽车平顺性和舒适性的重要措施之一。因此,必须对桥壳强度、刚度和动态特性进行力学分析。

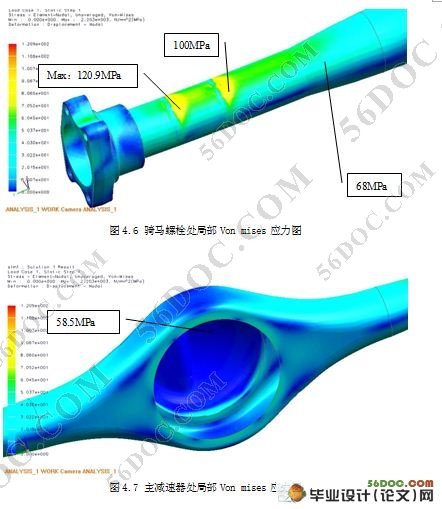

本文以有限元法静、动态分析理论为基础,使用有限元软件NX Nastran,对上汽通用五菱D150驱动桥桥壳进行分析。为了得到更为准确的分析结果,本文提出了独创性的分析方案,即应用的分析模型引入了弹簧钢板,使驱动桥桥壳的分析计算建立在接近实际的工作环境中。按照此思想完成了从三维几何建模到有限元分析的整个过程,得出桥壳在最大铅垂力工况、最大制动力工况和最大侧向力工况三种典型工况下的应力分布和变形结果以及在自由状态下的前20阶固有频率和振型。

本桥壳的有限元分析结果显示,桥壳内的最大Mises应力小于许用应力值,该桥壳满足强度要求,桥壳的每米轮距最大变形量小于国标规定的1.5mm/m满足刚度要求;计算得到的最低阶固有频率远大于路面激励频率,路面行驶不会引起桥壳共振。计算结果表明,在汽车各种行驶条件下该桥壳是安全可靠。并根据分析结果提出了桥壳的改良意见,使桥壳的设计最优化。 [资料来源:http://www.THINK58.com]

关键词:汽车驱动桥桥壳,有限元法,强度分析,模态分析

Abstract

Because the driving condition of the vehicle is very complex,the strength and dynamic performance of the drive axle housing affect the operation safety of the vehicle. The reasonable design of the drive axle housing is one of the importance ways to improve the ride comfort. Thus, it is necessary to analyze the strength,rigidity and dynamic performance of the drive axle housing.

Based on the static and dynamic theory of the finite element method,the axle housing-D150 of SAIC-GM-Wuling is analyzed by the FEM software NX Nastran in this paper. In order to obtain more accurate results of the analysis, this paper presents an analysis of original program. Analysis model introduced in the spring plate,so that the analysis calculation of the axle housing close to the actual working environment. In accordance with this thinking complete the whole process from the 3-D modeling to finite element analysis. And get the results of the stress distribution and deformation in three loading cases: the drive axle housing bears the maximum vertical force, the maximum braking force and the maximum lateral force. And the first twenty natural frequencies and modes under the free constraint are obtained in the modal analysis. [来源:http://think58.com]

The results of the finite element analysis show that the maximum Mises stress of the axle housing is less than the allowable stress value. So the axle housing meets the strength requirement. The maximum deformation per meter of the wheel center distance is less than 1.5mm/m, which meets the stiffness requirements in national standards. The minimum natural frequency calculated is far bigger than the frequency from road excitation. The resonance of the axle housing won’t happen when this automobile is traveling on road. The analyzed results tell us that the axle housing is safe and reliable under all kinds of driving conditions. And based on the results of analysis, make a suggest to improve the drive axle housing, so that the drive axle housing design optimization.

Key words: automotive drive axle housing, finite element method, strength analysis,model analysis

车桥是汽车的重要部件,其性能直接影响着汽车的整体性能。驱动桥壳的性能直接影响汽车的有效使用寿命和行驶的安全性。本论文基于D150驱动桥桥壳模型,对桥壳进行静力分析和模态分析,研究桥壳的静动态特性,为该系列驱动桥桥壳的优化设计和变型设计的可行性提供参考。 [来源:http://www.think58.com]

本课题为上汽通用五菱D150驱动桥桥壳的研究内容。

课题研究方法与主要内容

汽车驱动桥桥壳是汽车上的主要承载构件之一,其形状复杂,而汽车的行驶条件又是千变万化的,因此要精确地计算汽车行驶时作用于桥壳各处应力的大小是很困难的。通常情况下,在设计桥壳时多采用传统设计方法,这时将桥壳看成简支梁并校核某特定断面的最大应力值。我国通常推荐:将桥壳复杂的受力状况简化成三种典型的计算工况,即当车轮承受最大的铅垂力时;当车轮承受最大切向力时;以及当车轮承受最大侧向力时。只要在这三种载荷计算工况下桥壳的强度得到保证,就认为该桥壳在汽车各种行驶条件下是可靠的。

有限单元法是一种现代化的结构计算方法,在一定前提条件下,它可以计算各种机械零件的几乎所有几何部位的应力和应变。在国外,20世纪70年代以后,这种方法就逐渐为汽车零件的强度分析所采用,对汽车驱动桥桥壳的强度分析也不例外,国内、外都曾用它分析过汽车驱动桥桥壳的静、动态强度问题,但对于车桥厂而言,典型工况的有限元计算更具有现实的工程意义。本文以有限元法对五菱D150驱动桥桥壳进行了典型工况下的强度计算。

主要工作内容有:

(1)通过查阅文献资料,了解汽车驱动桥桥壳结构强度与模态分析这一领域的国内外研究现状及发展趋势,了解影响桥壳强度的主要因素;

[来源:http://think58.com]

(2)学习有限元的基本理论与概念,为后续工作奠定理论基础;

(3)研究使用UG高级仿真模块建立有限元模型的过程和步骤;

(4)对桥壳进行静态分析(三种典型工况的分析:最大铅垂力工况、最大制动力工况和最大侧向力工况)和模态分析(计算桥壳的振动模态和固有频率);

(5)分析所得的结果,判断桥壳的强度水平。