双油管采油树关键机械结构设计(含CAD零件图装配图)

1.无需注册登录,支付后按照提示操作即可获取该资料.

2.资料以网页介绍的为准,下载后不会有水印.资料仅供学习参考之用.

密 惠 保

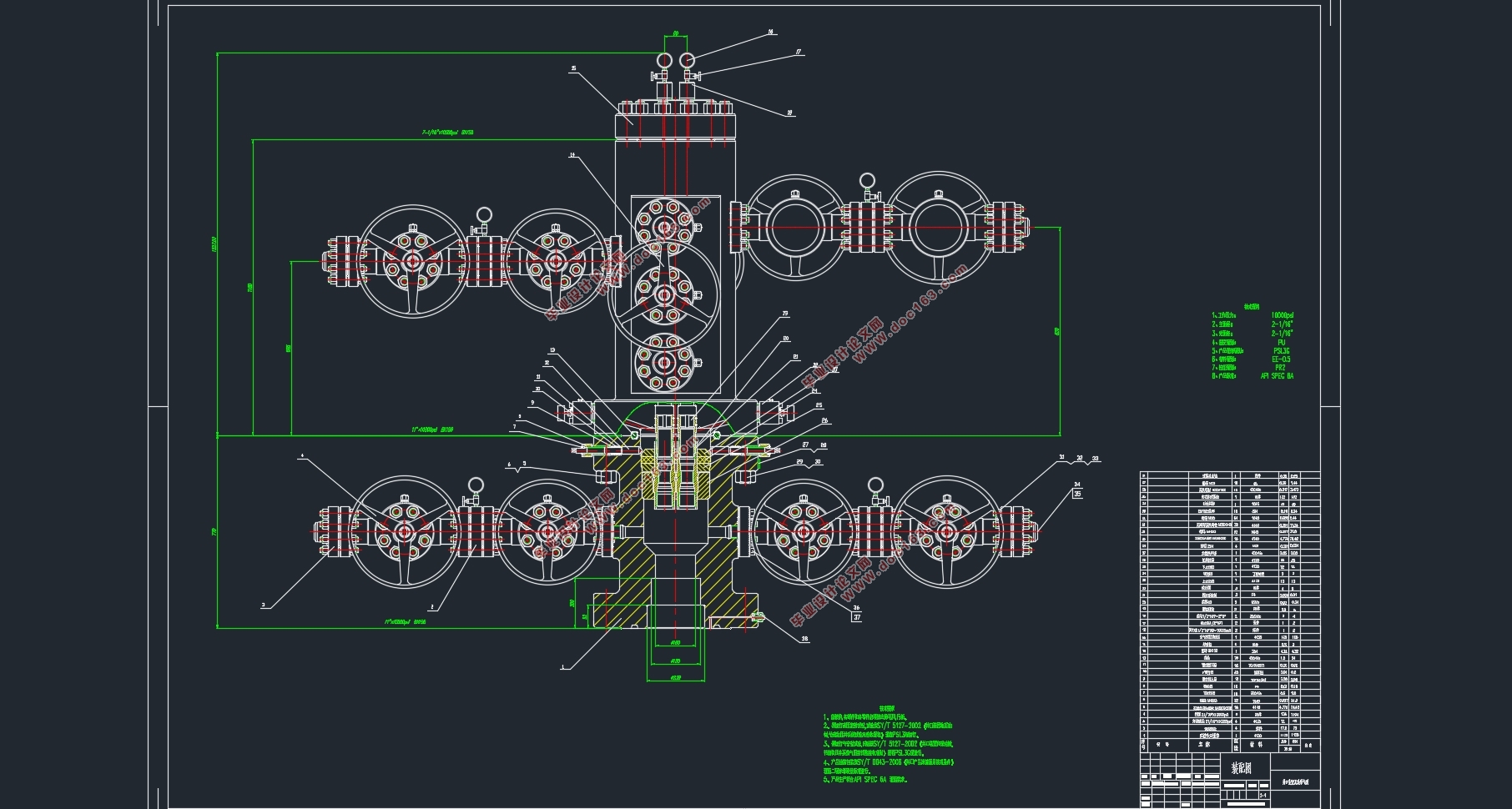

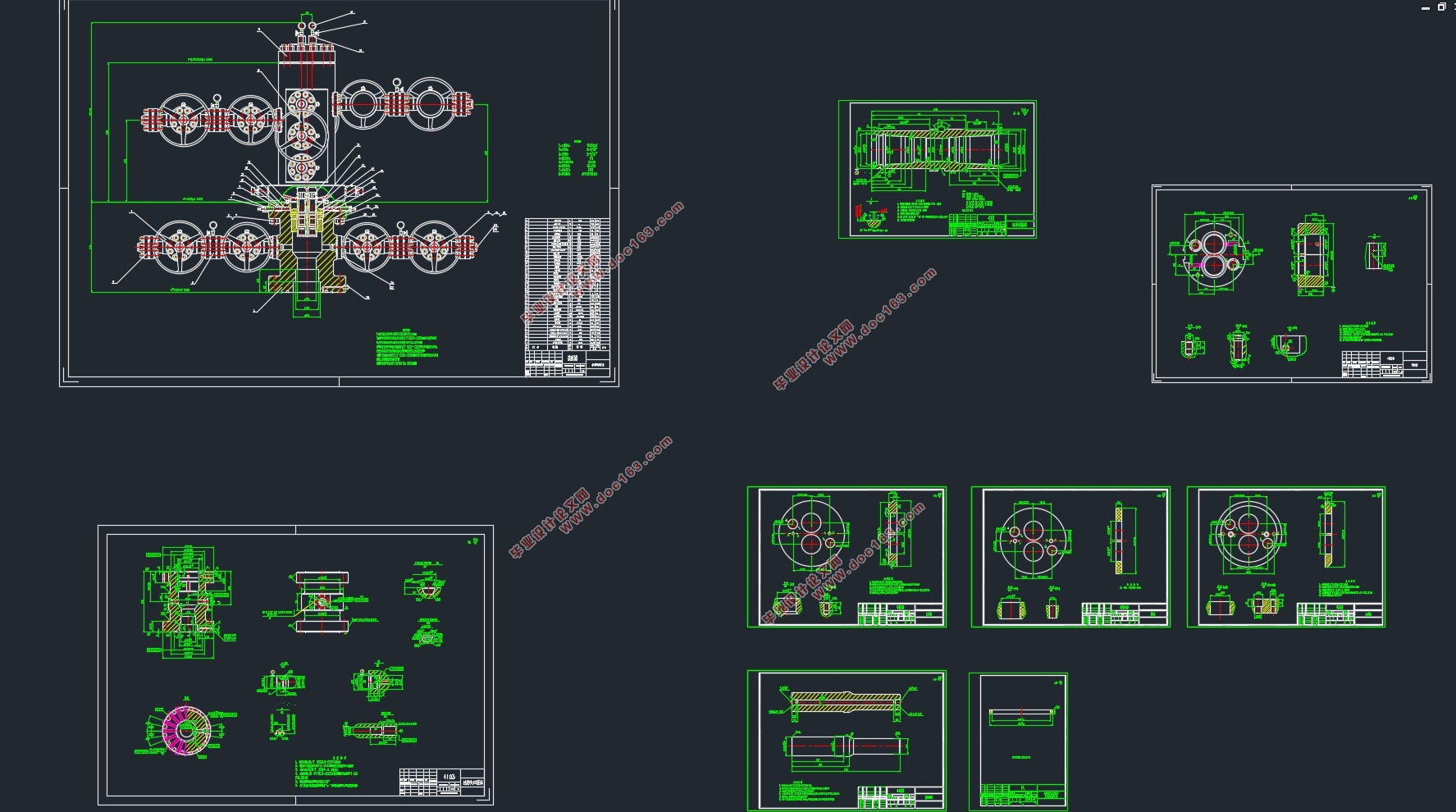

双油管采油树关键机械结构设计(含CAD零件图装配图)(任务书,开题报告,外文翻译,文献摘要,论文说明书12000字,CAD图9张)

摘要

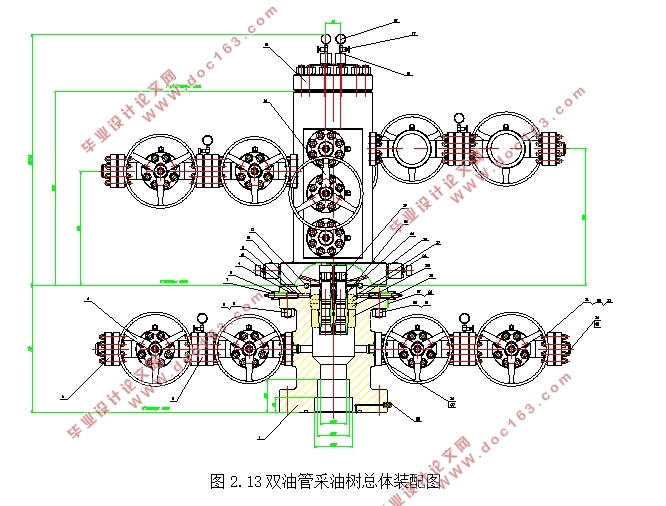

双油管采油树是井口装置的一种,不同于单油管井口装置面对复杂油田的局限,其特殊在于可以应用在不同油层的油田开采,而且开采效率比单油管井口装置更高,对油田环境的适应性更强。本文根据复杂油层的作业要求,开展了对于双油管采油树关键机械结构的设计研究。

根据API SPCE 6A 相关技术规范,在查阅了有关双油管井口装置的资料和对比了单油管井口装置结构特点,详细的分析了它应该所具有的功能并且相应的提出实现方法,之后提出了一个双油管采油树的总体设计方案。然后,对采油树、油管头大四通、双油管悬挂器、连接法兰、锁紧结构、密封结构、阀体进行了选择比较和详细的结构设计。

因为油管头主要由大四通、油管悬挂器等组成,它是整个双油管井口装置的核心部分,所以,结合大学所学的材料力学、理论力学和工程材料等课程,完成了大四通,油管连接轴的强度校核计算,包括壁厚强度校核,拉伸强度校核。为了更好的反应连接油管柱的油管连接轴的受力情况,还对油管连接轴进行了三维建模,并用ANSYS有限元分析软对其作了简单的应力分析。

最后对这次毕业设计做出了简要总结,并展望了上有关采油树的下一步研究工作。

关键词:双油管采油树、结构设计、强度校核、有限元分析

ABSTRACT

Double tubing X-mas tree is a kind of wellhead device, which is different from the limitation of a single tubing wellhead device in the face of complex oilfields. Its speciality is that it can be used in oil fields with different oil layers, and the extraction efficiency is higher than that of a single tubing wellhead device. The adaptability is stronger. In this paper, according to the operational requirements of complex reservoirs, the design and research of the key mechanical structure of the double tubing Christmas tree are carried out.

According to the API SPCE 6A related technical specifications, after consulting the data on the dual tubing wellhead device and comparing the structural characteristics of the single tubing wellhead device, detailed analysis of the function it should have and the corresponding method of implementation was proposed. Afterwards, a double was proposed. The overall design of the tubing tree. Then, a comparison and detailed structural design of the tree, tubing head, double tubing hanger, connecting flange, locking structure, sealing structure, and valve body were performed.

Because the tubing head is mainly composed of a large four-way pipe, a tubing hanger, etc., it is the core part of the entire double tubing wellhead device. Therefore, combined with the materials mechanics, theoretical mechanics, and engineering materials that the university has learned, it has completed the Big Four, The strength check calculation of the tubing connection shaft includes the wall thickness strength check and the tensile strength check. In order to better respond to the stress of the tubing connecting shaft connecting the tubing string, the tubing connecting shaft was also modeled in three dimensions, and a simple stress analysis was performed using ANSYS finite element analysis.

Finally, a brief summary of the graduation design was made and the next step in the research on the X-mas tree was prospected.

Keywords:double tubing X-mas tree, structural design, strength check,Finite element analysis

双油管采油树主要零部件的设计、计算校核

本次毕业设计课题中主要是设计了双油管采油树的油管头部分。查阅API SPCE 6A设计标准,确定的油管头技术规格如下: [资料来源:www.THINK58.com]

工作压力:10000Psi(69MPa)

上部连接法兰:11"×10000Psi BX158

下部连接法兰:11"×10000Psi BX158

主通径:2-1/16"

旁通径:2-1/16"

最小垂直通径:φ160mm

温度级别:PU

材料级别:EE-0.5

产品规范级别:PSL3G

性能级别:PR2

产品标准:API 6A

目录

第1章 绪论 1

1.1研究目的及意义 1

1.2国内外发展趋势及研究现状 1

1.3毕业设计内容及时间安排 5

第2章 双油管采油树井口装置总体方案设计 6

2.1双油管采油树井口装置功能分析 6 [资料来源:www.THINK58.com]

2.1.1悬挂连接油管 6

2.1.2 对油管悬挂器的承力 6

2.1.3 井口装置的密封 6

2.1.4 各种电缆井下下放 6

2.1.5正反洗井功能 6

2.1.6 井下流体的控制功能 6

2.2 双油管采油树井口装置功能实现方法 7

2.2.1悬挂连接油管功能实现 7

2.2.2 对油管悬挂器的承力功能实现 7

2.2.3 井口装置的密封功能实现 9

2.2.4各种电缆井下下放和功能实现 10

2.2.5 正反洗井功能实现 11

2.2.6井下流体控制的功能实现 12

2.3双油管采油树井口装置总体方案 14

第3章 双油管采油树主要零部件的设计、计算校核 16

3.1 法兰及其连接螺栓的规格型号选择 16

3.2油管头大四通的尺寸确定以及计算校核 18

3.2.1 油管头大四通基本尺寸的确定 18

3.2.2油管四通体强度计算 19

[资料来源:THINK58.com]

3.3密封结构及密封件的选择 21

3.4法兰连接螺栓的计算 23

3.5油管连接轴的强度计算 24

3.5.1 油管连接轴壁厚校核 24

3.5.2油管连接轴拉伸强度校核 25

3.5.3油管连接轴有限元分析 26

第4章 总结与展望 32

4.1研究总结 32

4.2研究展望 32

参考文献 34

致谢 35