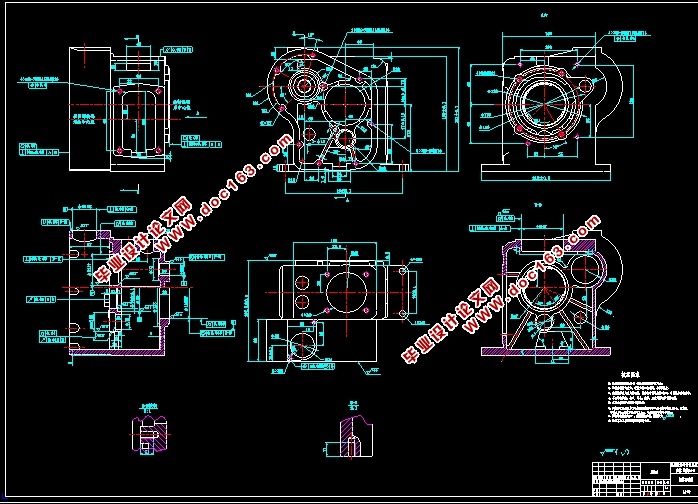

柴油机壳体加工工艺及Φ66镗孔夹具设计(含CAD图,工序卡)

1.无需注册登录,支付后按照提示操作即可获取该资料.

2.资料以网页介绍的为准,下载后不会有水印.资料仅供学习参考之用.

密 惠 保

设计题目:柴油机壳体加工工艺及Φ66镗孔夹具设计(含CAD图,工序卡)(论文说明书18000字,CAD图纸6张,工序卡,实习调研报告)

摘要

这次毕业设计是编制壳体类零件的加工工艺,箱体类零件是用来把各个部件按照一定的顺序和配合安装在一起,使各部件之间有正确的位置关系,并且能够有相对的运动。箱体类零件的加工工艺设计首先是根据图纸上的要求,选择合适的加工手段和方法,编制相应的工艺并从中选出较优的工艺方案,并对每一道工序进行计算,包括机床的选择,刀具选用,进给量、切削工时的计算,最后对其中一道工序所用的夹具进行设计。在制定工艺前,要明确各工序的基准,在夹具设计前,要明确具体工序的定位、夹紧方式,进而选择夹具的轮廓,在设计夹具时,要尽量选用标准件,以方便后续夹具的保养与维修。

关键词:工序、定位、夹紧、夹具设计

Abstract

The graduation project is to compile the processing technology of shell parts.The box parts are used to install each component in a certain order and fit together, sothat each component has the correct position relation and can have relative motion. [来源:http://think58.com]

First of all, according to the requirements of drawings, the process design of box partsis to select the appropriate processing means and methods, to draw up thecorresponding process and to select the better process plan, and to calculate each

working procedure, including the choice of machine tools. Tool selection, feed rateand cutting time are calculated. Finally, the fixture used in one of the processes isdesigned. Before working out the process, be clear about the work Before the fixture

design, the position of specific working procedure and clamping mode should bedefined, and then the contour of fixture should be selected. When designing thefixture, the standard parts should be chosen as far as possible to facilitate the

[资料来源:http://think58.com]

maintenance and repair of the subsequent fixture.

Keywords: The process, The localization, clamps, jig design

[资料来源:http://think58.com]

目录

摘要 ...................................................................................................................................I

Abstract.............................................................................................................................. II

CONTENTS .......................................................................................................................3

第一章绪论 ......................................................................................................................5

1.1 机械制造工艺的发展 .........................................................................................5

1.1.1 机械制造业的发展 ......................................................................................5

1.1.2 机械制造工艺的重要性 ..............................................................................5

1.2 机床夹具 .............................................................................................................6

1.2.1 机床夹具及其组成 ......................................................................................6

1.2.2 机床夹具的分类 ..........................................................................................6

第二章柴油机壳体加工工艺及其Φ66镗孔夹具设计方案设计及可行性论证 .........7 [来源:http://www.think58.com]

2.1 柴油机壳体加工工艺及其Φ66镗孔夹具设计方案设计 ................................7

2.1.1 方案 1 ...........................................................................................................7

2.1.2 方案 2 ...........................................................................................................8

2.1.3 方案 3 ...........................................................................................................8

2.2 柴油机壳体加工工艺及其Φ66镗孔夹具设计方案设计方案可行性论证 ....9

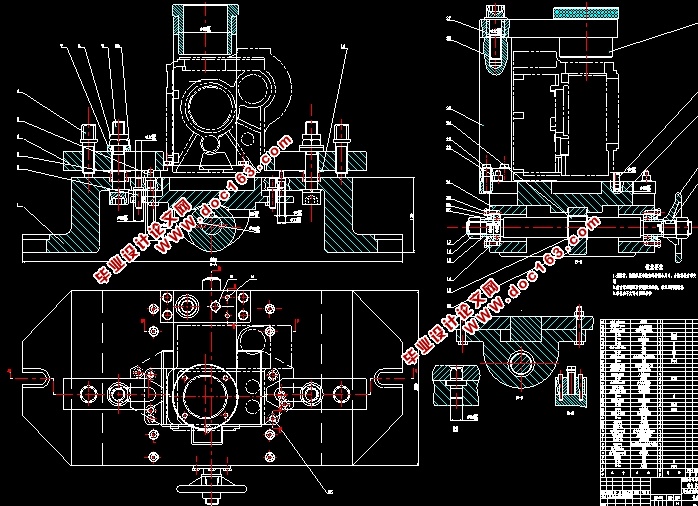

2.3 夹具的设计 .......................................................................................................10

第三章工序设计与计算 ................................................................................................. 11

3.1 零件分析 ........................................................................................................... 11

3.1.1 机体的主要作用 ........................................................................................ 11

[资料来源:http://think58.com]

3.2 主要技术条件分析 ........................................................................................... 11

3.2.1 形位误差的要求及分析 ............................................................................ 11

3.2.2 主要尺寸公差及分析 ................................................................................13

3.2.3 表面粗糙度要求 ........................................................................................14

3.3 毛坯的确定 .......................................................................................................14

3.3.1 毛坯材料的选择及制造形式的确定 ........................................................14

3.3.2 铸造的加工余量及尺寸公差得确定 ........................................................14

3.4 定位基准选择 ...................................................................................................15

3.4.1 粗基准的选择 ............................................................................................15

3.4.2 精基准的选择 ............................................................................................16

3.5 制订加工工艺路线 ...........................................................................................16

3.5.1 刀具、量具、夹具及设备的选择 ............................................................18

3.5.2 加工工序的设计 ........................................................................................21

3.6 夹具设计 ...........................................................................................................39

3.6.1 定位的选取 ................................................................................................39

3.6.2 结构组成 ....................................................................................................40

3.6.3 各元件的设计 ............................................................................................40

3.6.4 定位误差分析 ............................................................................................40

[资料来源:http://THINK58.com]

3.6.5 夹具标准件的选择原则 ............................................................................42

3.7 环境保护和可持续发展方面的考虑 ...............................................................43

3.7.1 设计产品时的环保考虑 ............................................................................43

3.7.2 产品设计时的可持续发展考虑 ................................................................43

第四章夹具的使用及维护 .............................................................................................44

4.1夹具的使用 ........................................................................................................44

4.2夹具的维护 ........................................................................................................44

第五章毕业设计特色专题 ............................................................................................45

5.1 建模软件的介绍 ...............................................................................................45 [资料来源:THINK58.com]

5.2 零件的建模 .......................................................................................................45

5.2.1 预定位凸台 ................................................................................................45

5.2.2 轴 ................................................................................................................46

5.2.3 心轮 ............................................................................................................46

5.2.4 夹具 ............................................................................................................47

5.2.5 柴油机三维模型 ........................................................................................47

结论 ................................................................................................................................48

参考文献 ..........................................................................................................................49 [版权所有:http://think58.com]

致谢 ................................................................................................................................51

[版权所有:http://think58.com]

上一篇:阀体的加工工艺编制及夹具设计(含CAD图,CAXA图纸,工艺卡)

下一篇:831006拨叉机械加工工艺及夹具设计(含CAD零件装配图,工序卡)