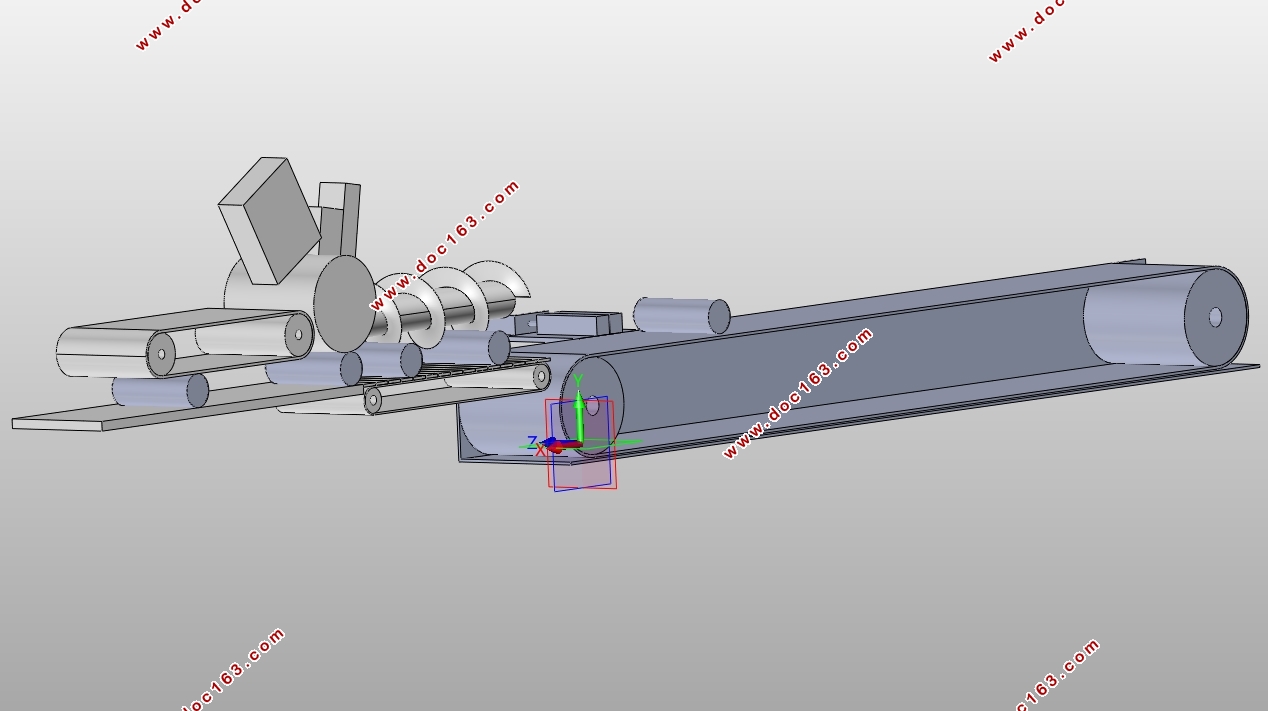

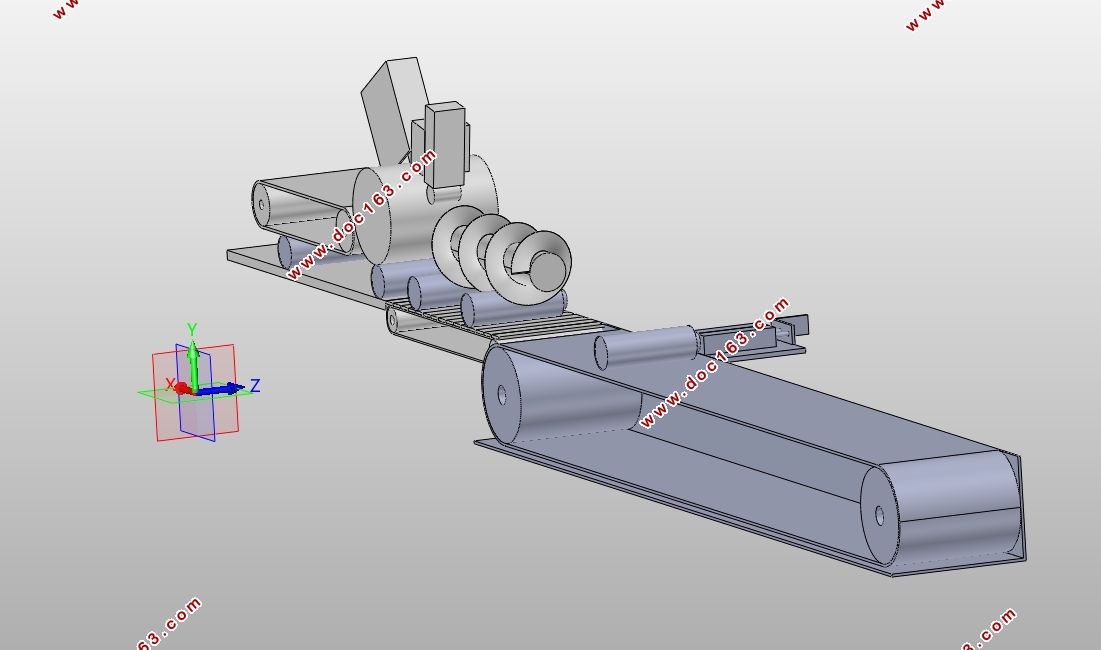

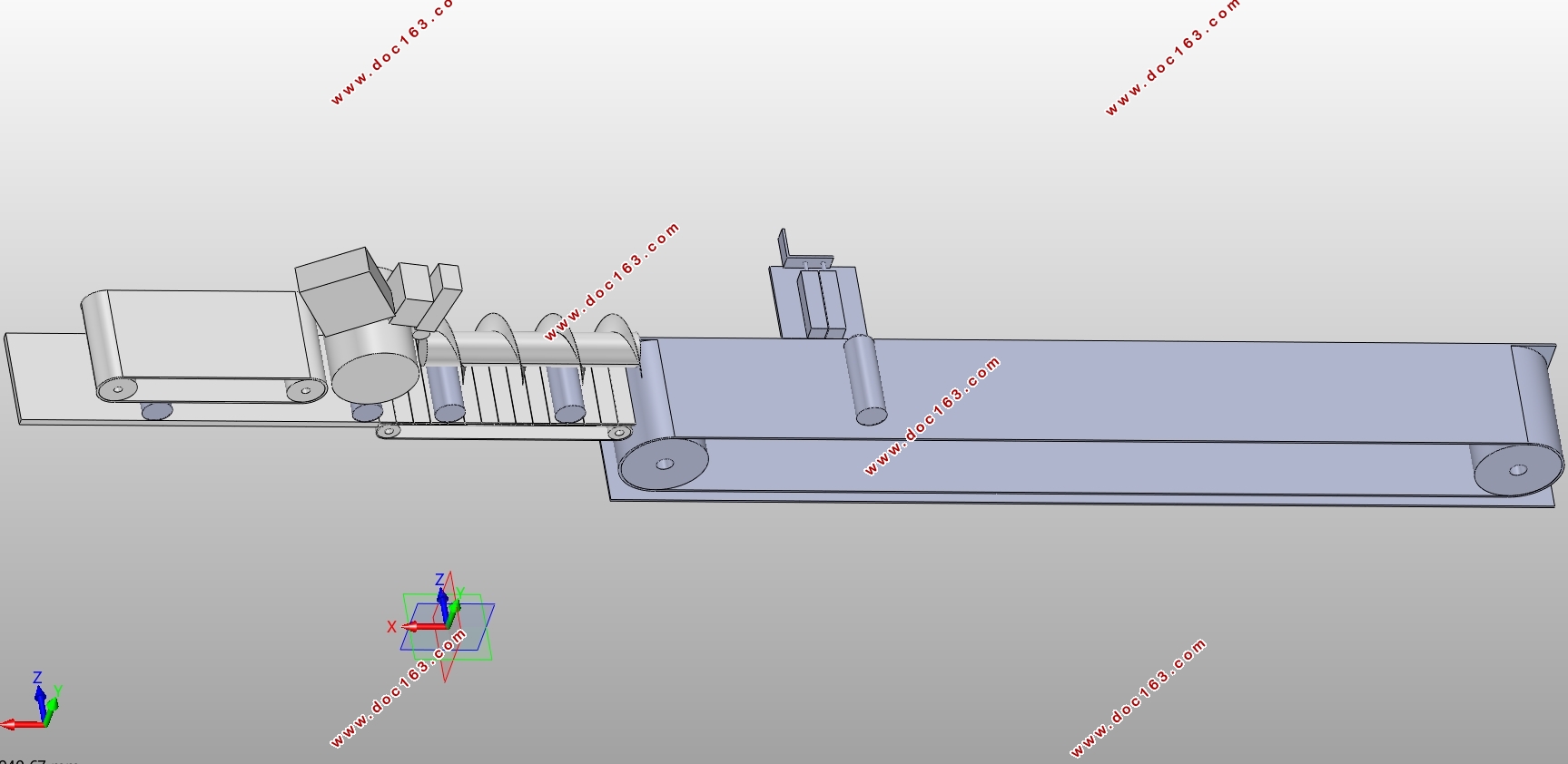

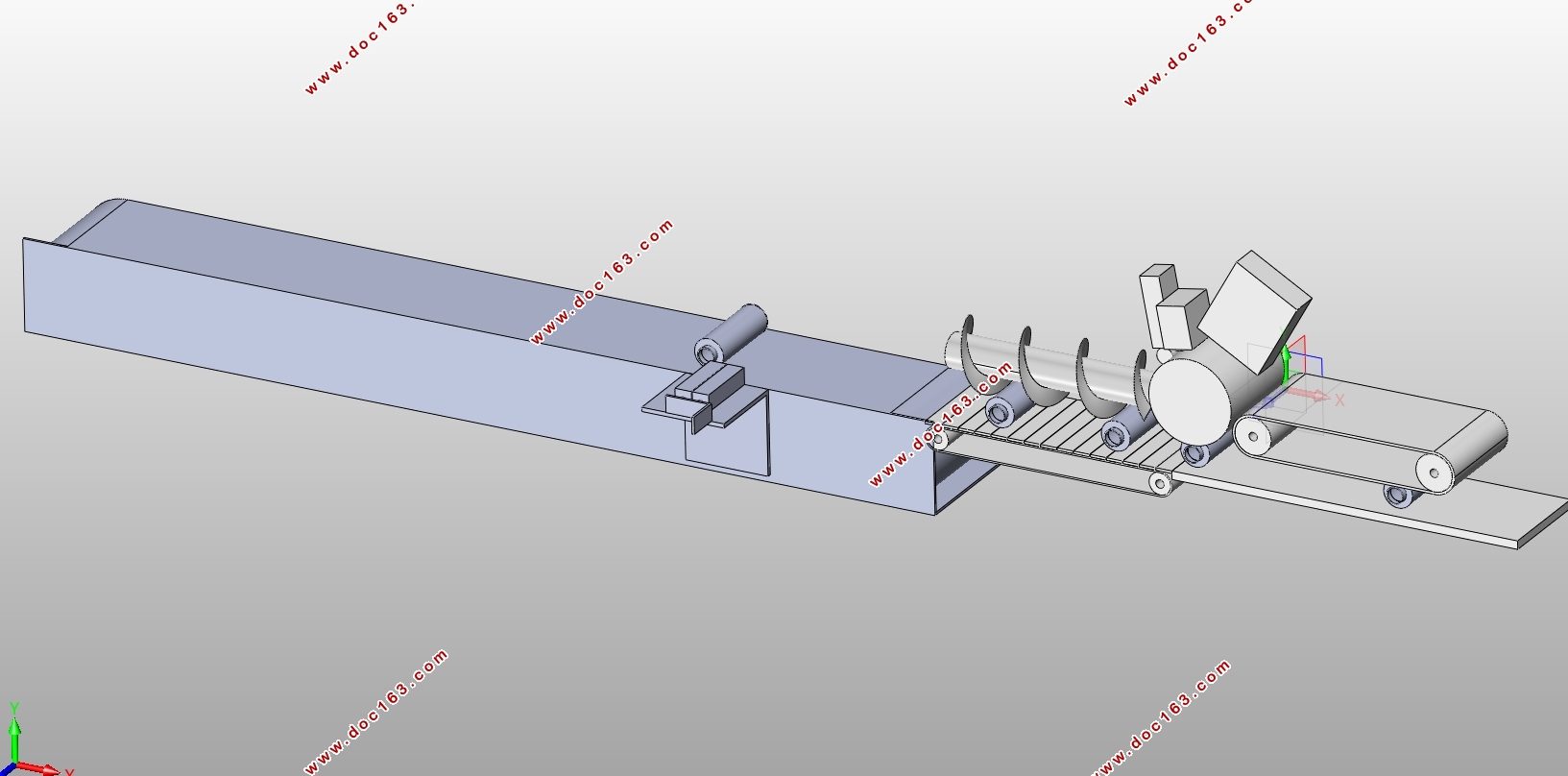

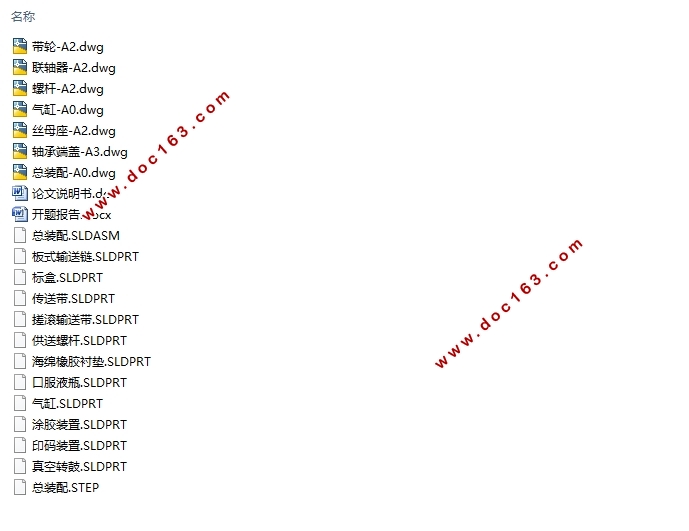

口服液检测剔瓶及贴标机构设计(含CAD零件装配图,SolidWorks三维图)

1.无需注册登录,支付后按照提示操作即可获取该资料.

2.资料以网页介绍的为准,下载后不会有水印.资料仅供学习参考之用.

密 惠 保

口服液检测剔瓶及贴标机构设计(含CAD零件装配图,SolidWorks三维图)(开题报告,论文说明书14000字,CAD图7张,SolidWorks三维图)

摘要

近十年来,我国科技开始飞速发展。人们生活水平是越来越高。随着人们生活的富裕,对于物质生活的要求也随之提高。不仅对于商品的品质有要求,对于商品的包装也有了不同的要求。同一种商品经过不同档次的包装,就可以售出不同的价位。这对于人们丰富的物质生活来说是必不可少的。

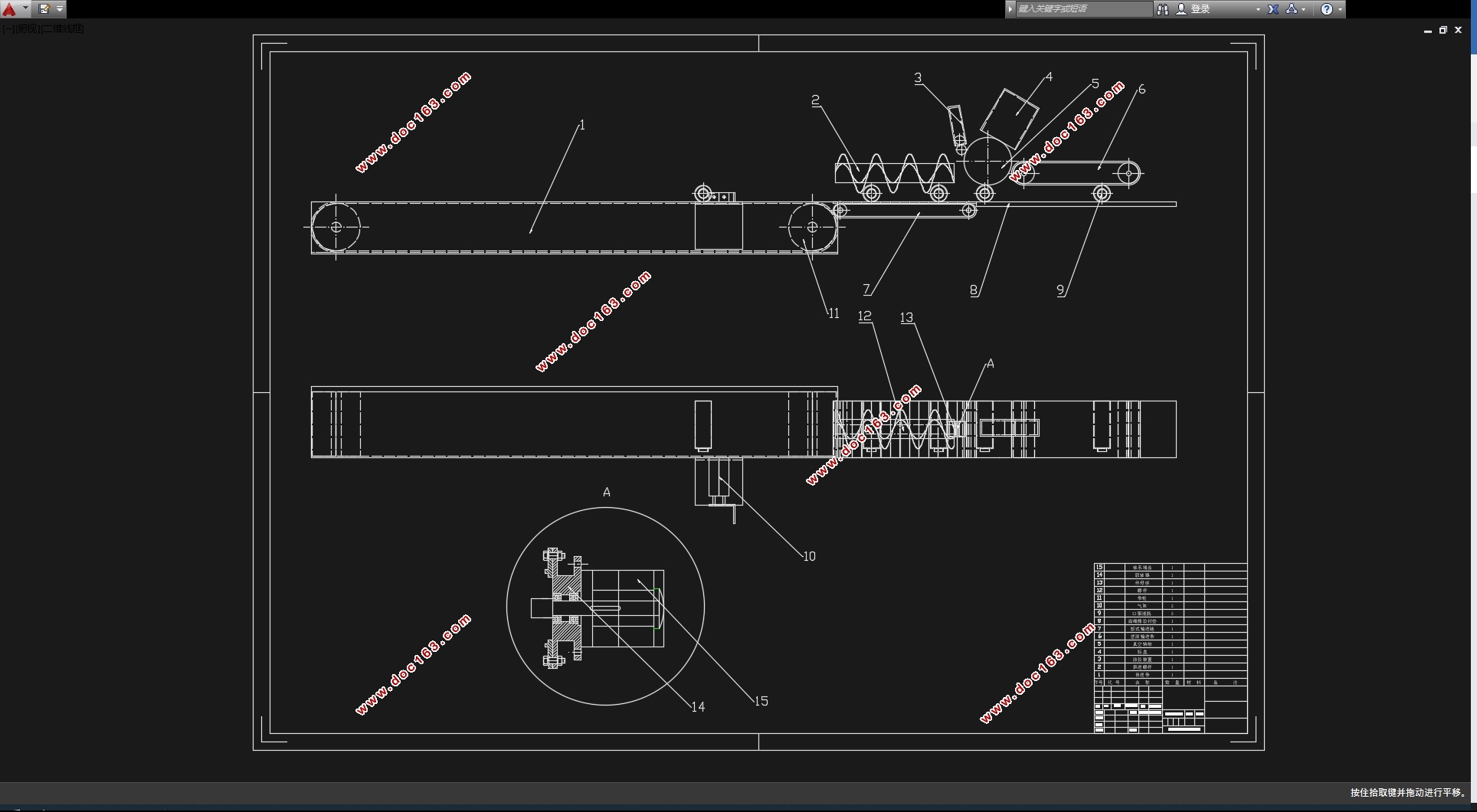

本文设计的主题是口服液瓶的检测剔瓶和贴标机构。是包装产业的一种。口服液需要经过机械化的生产,首先需要对口服液瓶进行清洗和消毒。然后对口服液瓶进行灌装和封盖。灌装完成后就会对口服液瓶进行检测和贴标。检测的目的是发现灌装过程中出现的未灌满或者瓶子本身有质量原因导致的漏液和渗液。本文主要是对执行系统、传动系统分析、计算、校核,确定运动、动力参数,选择适合的动力及结构、检测、控制等标准件、元器件等。方案设计。绘制机构简图、系统原理图等,通过技术、经济评价,确定实施方案。

对传动系统、执行系统设计与计算。主要包括机构的运动设计与计算、结构设计与计算、动力选择与参数计算等。对结构设计。包括总体结构设计;传动部分、检测、剔除、取标、贴标等执行部分部装图设计,零件图设计等任务。

[来源:http://www.think58.com]

本文的主要目的是为了强化对机械机构知识的灵活运用,将书本知识实际运用到设备的设计与优化上。同时,也是为了了解国内食品包装行业的发展趋势和现状,针对目前的发现提出可行性的研究方案和意见。

关键词:检测机构;贴标机构;口服液;自动化

ABSTRACT

In the past decade, China's technology has begun to develop rapidly. People's living standards are getting higher and higher. With the prosperity of people's lives, the requirements for material life have also increased. Not only do they have requirements for the quality of the goods, but they also have different requirements for the packaging of the goods. The same product can be sold at different prices after being packaged in different grades. This is essential for people's rich material life.

The theme of this article is the detection, bottle removal, and labeling mechanism for oral liquid bottles. It is a type of packaging industry. Oral liquid requires mechanized production, and first, oral liquid bottles need to be cleaned and disinfected. Then fill and cap the oral liquid bottle. After filling, the oral liquid bottle will be tested and labeled. The purpose of testing is to detect leakage and seepage caused by underfilling or quality issues with the bottle itself during the filling process. This article mainly analyzes, calculates, and verifies the execution system and transmission system, determines the motion and power parameters, selects suitable standard components and components such as power and structure, detection, and control. Scheme design. Draw a schematic diagram of the organization, system schematic diagram, etc., and determine the implementation plan through technical and economic evaluation.

[资料来源:http://think58.com]

Design and calculate the transmission system and execution system. This mainly includes the motion design and calculation of the mechanism, structural design and calculation, power selection and parameter calculation, etc. Regarding structural design. Including overall structural design; Perform tasks such as assembly drawing design and part drawing design for the transmission part, inspection, removal, labeling, and labeling.

The main purpose of this article is to strengthen the flexible application of mechanical mechanism knowledge and apply book knowledge to the design and optimization of equipment. At the same time, it is also to understand the development trend and current situation of the domestic food packaging industry, and to propose feasible research plans and opinions based on the current findings.

Keywords: testing institutions; Labeling agency; Oral liquid; automation

主要参数:

生产率:不低于100瓶/分钟;

商标尺寸为80×30 mm;

口服液尺寸:口服液瓶高107mm,外径35mm。

[来源:http://think58.com]

1.3.2 设计要求:

(1)电源电压:380V/50Hz;

(2)要实现检测、剔除、取标和贴标;

(3)生产率不低于100件/分钟;

[来源:http://www.think58.com]

目录

摘要 I

ABSTRACT II

1 绪论 3

1.1 本课题的研究内容和意义 3

1.2 国内外的发展概况 3

1.3 预期达到的目标 3 [资料来源:THINK58.com]

1.3.1 主要参数: 3

1.3.2 设计要求: 4

1.3.3 拟完成的工作量 4

2 工艺路线确定 5

2.2 确定工艺路线,画出工艺路线图 5

2.3 口服液检测剔瓶及贴标机构的总体工艺路线 5

2.4 各功能及其工作原理 6

3 总体方案对比 8

3.1 功能分解,画出功能树 8

3.2 确定功能机构 8

四 传动装置的计算 11

4.1 电动机的选择 11

4.1.1 电动机的类型和结构分析 11

4.1.2 选择口服液检测剔瓶及贴标机构电动机的功率 11

4.1.3 确定口服液检测剔瓶及贴标机构电动机的转速 12

4.2 计算总传动比及分配各级的传动比 12

4.3 运动参数及动力参数计算 13

4.3.1 各轴转速计算 13

4.3.2 各轴输入功率计算 13

4.3.3 各轴输入转矩计算 13

[来源:http://think58.com]

五 传动零件的设计计算 15

5.1 V带轮传动的设计计算 15

5.2 圆锥齿轮传动的设计计算 17

5.3 圆柱齿轮传动的设计计算 20

六 轴的设计计算 23

6.1 主动轴设计计算 23

6.2 锥齿轮输出轴设计计算 26

6.3 惰轮轴设计计算 28

由以上计算可知,轴的尺寸选用是符合要求的。七 键联接的选择及计算 29

7.1 电机与电动机带轮联接采用平键连接 30

7.2 主动轴与减速器机带轮联接采用平键连接 30

7.3 锥齿轮输出轴与小圆柱齿轮联接采用平键连接 30

7.4 锥齿轮输出轴与大锥齿轮联接采用平键连接 30

八 滚动轴承设计 32

8.1 主动轴的轴承设计计算 32

8.2 输出轴的轴承设计计算 33

九 自动送料机构工作方案设计 35

9.1控制系统的选择 35

9.2机架的设计 35

十 口服液检测剔瓶及贴标机构使用注意事项 36

10.1口服液检测剔瓶及贴标机构的日常使用及设备维护 36

10.2对于口服液检测剔瓶及贴标机构的操作规范及调整 36

10.3口服液检测剔瓶及贴标机构的保养 37

总 结 38

致 谢 39

参考文献 40 [资料来源:THINK58.com]