双柔索驱动的负压吸盘玻璃幕墙清洗装置设计(含CAD零件图装配图)

1.无需注册登录,支付后按照提示操作即可获取该资料.

2.资料以网页介绍的为准,下载后不会有水印.资料仅供学习参考之用.

密 惠 保

双柔索驱动的负压吸盘玻璃幕墙清洗装置设计(含CAD零件图装配图)(任务书,开题报告,论文说明书16000字,CAD图5张)

摘要

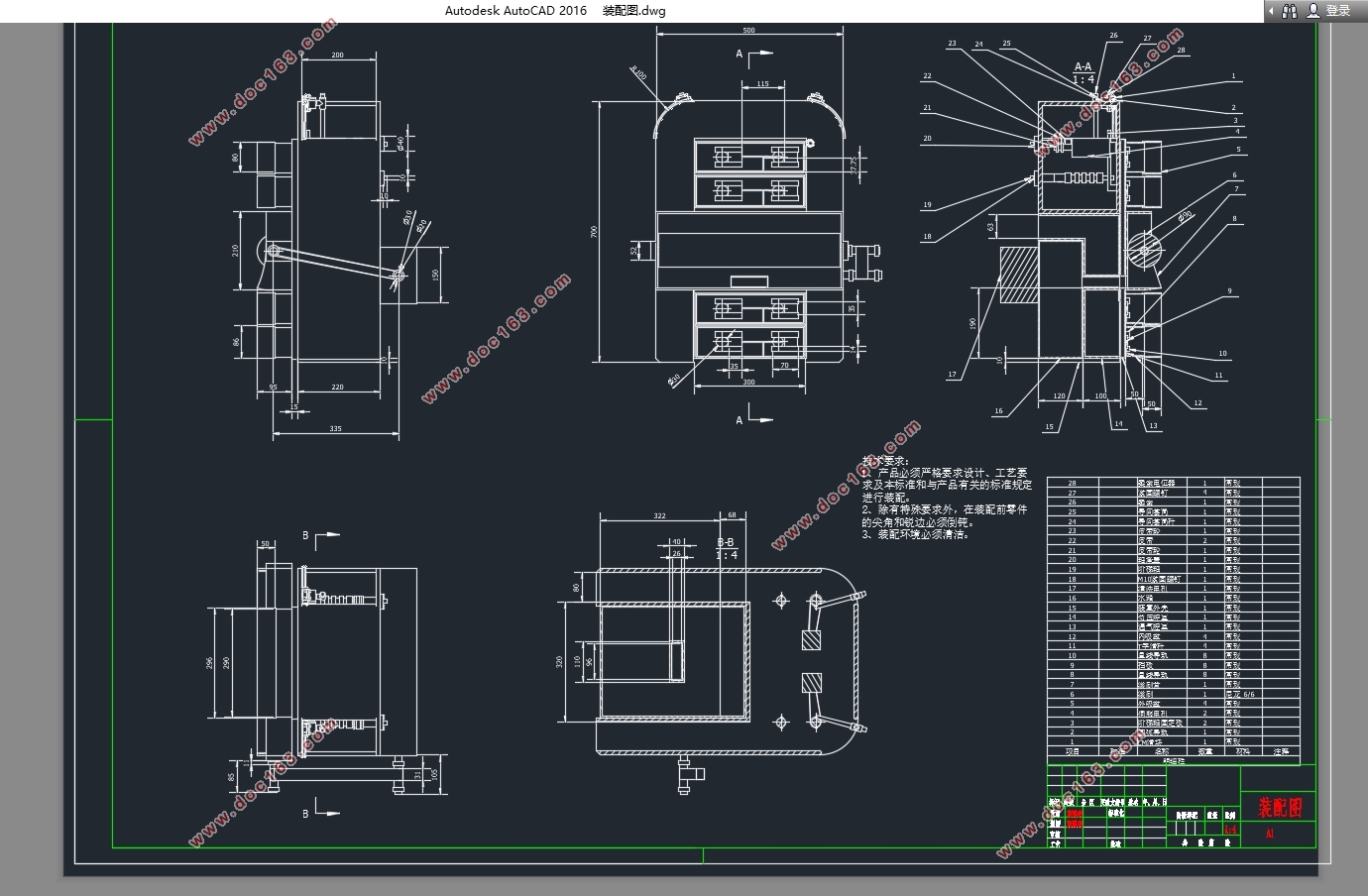

本文根据目前玻璃幕墙清洗作业的发展现状提出了一种新式高空玻璃幕墙清洗装置的方案并借助建模软件Inventor对整个装置进行了建模设计,该方案通过两根柔索分别系于建筑顶部左右端,另一侧分别绕过清洗装置左右侧的驱动辊,通过伺服电机驱动其柔索的配合收放与圆弧导轨引导的柔索角度辅助来控制清洗装置在壁面的灵活移动,同时辅以负压吸盘提供可靠的吸附能力,使得其能够牢固的吸附在壁面上,顺利完成清洗作业。

论文主要研究了清洗装置的各个部件结构选型与尺寸,柔索驱动过程中的受力分析,确定了柔索缠绕方式与装置自重与所需配重之间的关系,分析了清洗装置在工作中实际所能达到的工作空间,并提出了其作业动态的柔索收放模型,为控制系统的设计提供了基础。本文通过对清洗装置中重要零部件的强度校核与装置特殊位置时会产生的额外转矩进行分析,确定了其安全自重限制范围。

通过对清洗装置的各项选型与设计,相关分析与校核,最终确定了该装置的整体技术指标,与目前主流的清洗装置进行比较,具有清洗效率高,重量轻,小型化,灵活化等特点,对高空清洗作业的研究发展有一定的意义。 [资料来源:http://THINK58.com]

关键词:清洗装置;玻璃幕墙;双柔索;负压吸盘;Inventor;圆弧导轨;

Abstract

Based on the current development status of glass curtain wall cleaning operations, this paper proposes a new type of high-altitude glass curtain wall cleaning device and uses the modeling software Inventor to model and design the entire device. The solution is connected to the top of the building through two flexible cables. At the same time, the other side bypasses the drive roller on the left and right side of the cleaning device respectively, and the flexible motor can be controlled by the servo motor to drive the cooperative retraction of the flexible cable and the angle of the flexible cable guided by the circular guide rail to control the flexible movement of the cleaning device on the wall surface. The vacuum suction cup provides reliable adsorption capacity, enabling it to be firmly adsorbed on the wall surface and complete the cleaning operation smoothly.

The paper mainly studies the structure selection and size of each component of the cleaning device, the force analysis during the driving process of the flexible cable, and determines the relationship between the winding mode of the flexible cable and the device's own weight and the required weight, and analyzes the cleaning device at work. In the actual work space can be achieved, and put forward its operating dynamics of the cable retractable model, provides a basis for the design of the control system. This article analyzes the strength of the important components in the cleaning device and the extra torque that will be generated when the device is in a special position, and determines the safety weight limit range.

Through the selection and design of the cleaning device, correlation analysis and verification, the overall technical specifications of the device are finally determined. Compared with the current mainstream cleaning devices, the device has high cleaning efficiency, light weight, miniaturization, and flexibility. Such characteristics have a certain significance for the research and development of high altitude cleaning operations.

Key Words:cleaning robot;glass curtain wall;double cable;vacuum sucker;Autodesk Inventor;circular guide;

柔索移动单元总体尺寸:500x700x220 mm。

滚刷与吸盘到移动单元距离:110mm。

清洗单元尺寸:滚刷半径45mm,滚刷电机500x150x100mm,水箱300x316x120mm。

负压吸盘单元尺寸:负压腔室尺寸如图2.3所示,吸盘尺寸295x80mm,可伸缩长度为65-110mm,负压吸盘导通室590x300x15mm,中间通水箱100x30x100mm。

[版权所有:http://think58.com]

目录

第1章绪论 1

1.1 课题研究背景、目的及意义 1

1.2各种清洗机器人的分类比较 2

1.3目前国内外研究概况 2

1.3.1国外研究状况分析 2

1.3.2国内研究状况分析 3

1.4本文主要研究内容 4

第2章清洗装置方案设计 5

2.1设计目标 5

2.2清洗装置的结构功能设计与尺寸确定 5

2.2.1双柔索驱动的壁面全向移动单元 8

2.2.2负压吸盘单元 11

2.2.3滚刷清洗单元 13

第3章清洗装置本体机构设计与相关分析 15

3.1 双柔索驱动的移动单元的设计与分析 15

3.1.1辊轮槽数的计算 15

3.1.2圆弧导轨的设计与分析 17

3.1.3清洗装置工作空间与动态分析 18

3.2 负压吸盘单元 22

3.2.1吸附时清洗装置下滑作业中的受力分析 22

3.2.2清洗装置越障时动态分析 24

3.2.3安全性分析与计算 25

第4章清洗装置控制系统设计 27

4.1清洗装置总体控制系统的要求 27

4.2清洗装置本体控制系统的硬件设计 27

4.3清洗装置本体控制系统的软件设计 28

第5章总结与展望 30

参考文献 31

致谢 33

[来源:http://think58.com]