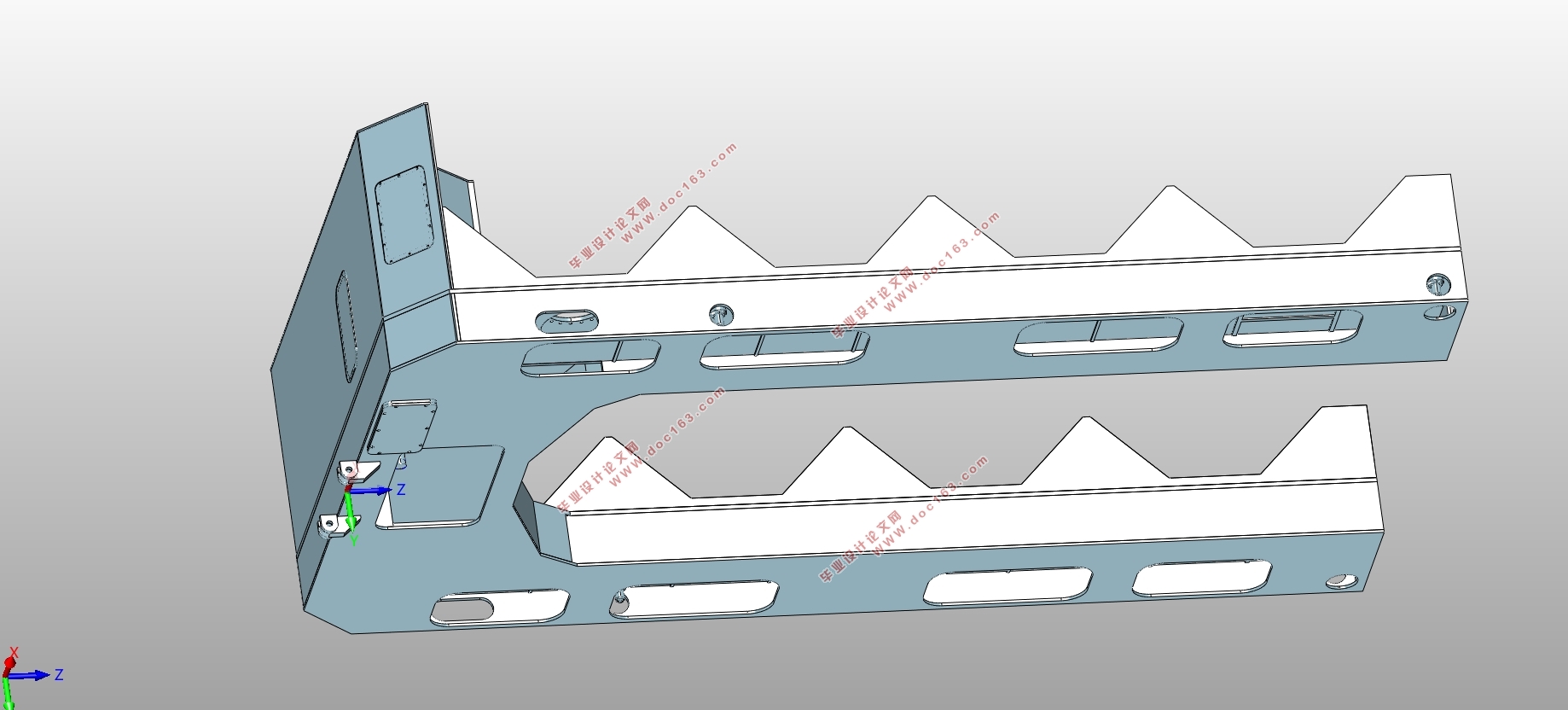

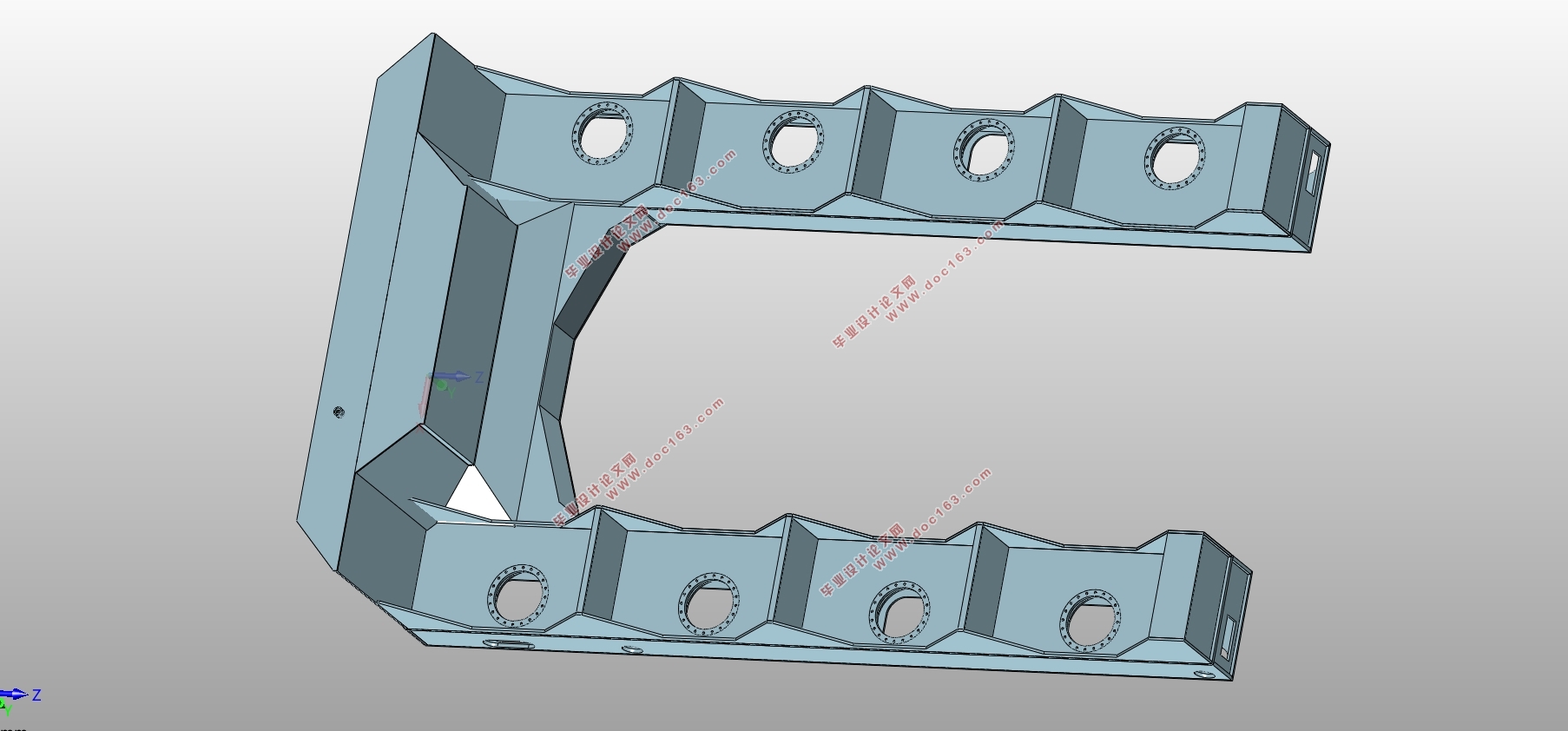

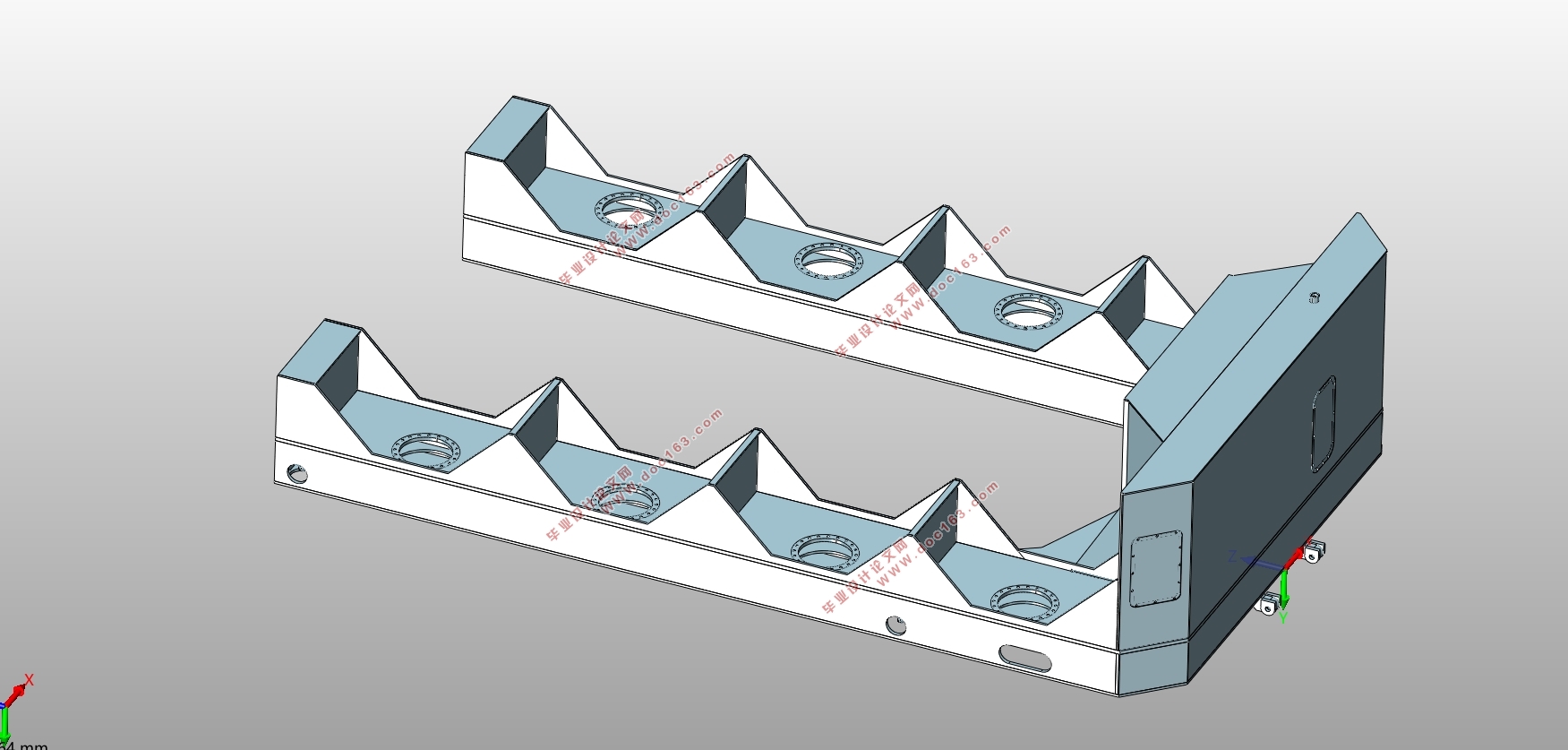

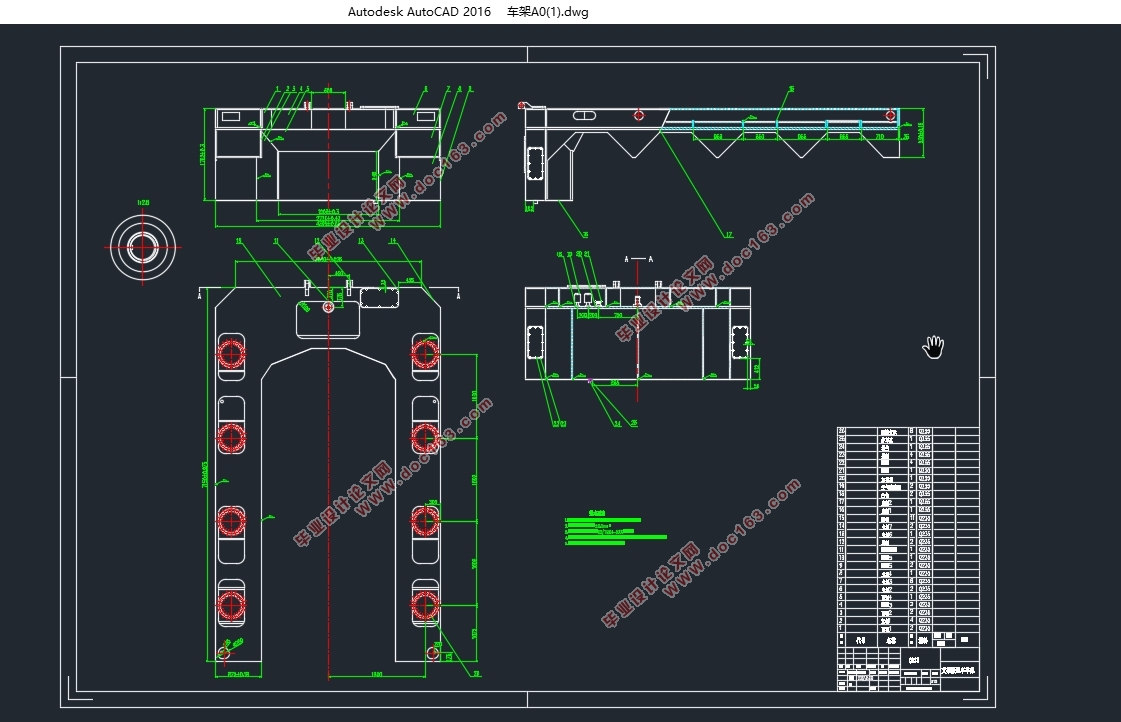

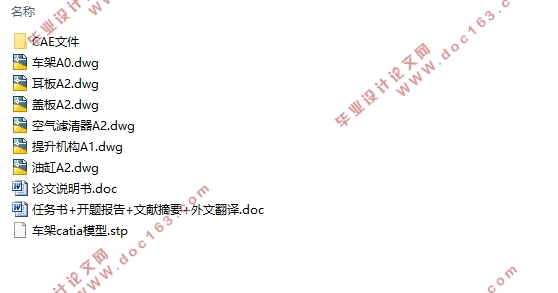

100t液压支架搬运车车架CAE分析与优化设计(含CAD图,CATIA三维图)

1.无需注册登录,支付后按照提示操作即可获取该资料.

2.资料以网页介绍的为准,下载后不会有水印.资料仅供学习参考之用.

密 惠 保

100t液压支架搬运车车架CAE分析与优化设计(含CAD图,CATIA三维图)(任务书,开题报告,文献摘要,外文翻译,论文说明书12000字,CAD图6张,CATIA三维图)

摘 要

本文借助强大的有限元分析前处理软件Hypermesh导入车架模型、抽取中面、几何清理并进行网格的划分与网格质量的检查,然后将处理好的有限元模型导入求解器ABAQUS,附加载荷及约束,计算出100t液压支架搬运车车架刚度与强度。对于应力过大处进行适当的优化设计,并再次验证是否符合刚度和强度要求,得到最终的车架模型。

论文主要研究了100t液压支架板搬运车车架的有限元分析方法,Hypermesh和ABAQUS在有限元分析中的具体应用,分析在承受载荷状况下所受的刚度和强度,并对应力集中处进行了改进。

研究结果表明:在提升机构所在平面为受力最集中处,此时施加100t的力并未超过材料极限,但我们仍然可以安装加强板以增加车架的刚度和强度。

本文的特色:本文的特色主要在于根据各个软件的优点来选用软件进行有限元分析,通过catia强大的建模功能来进行建模,通过Hypermesh强大的前处理功能进行网格划分,通过ABAQUS强大的计算能力添加约束和力计算刚度和强度,共同对车架进行有限元分析,得出刚度强度并进行优化设计。 [资料来源:http://think58.com]

关键词:车架;CAD/CAE;Hypermesh;ABAQUS;有限元分析;静力分析

Abstract

The paper uses the powerful finite element analysis preprocessing software Hypermesh to import the frame model,extract the midsurface,clean up the geometry ,divide the grid and check the quality of mesh.Then we transport the completed finite model into the solver ABAQUS.With additional load and constraints,the stiffness and strength of the frame were calculated. Lastly,we should optimize those exessive pressure structures.Then we can verify whether the stiffness and strength requirements are fitted,and get the final frame model.

This paper mainly studies the finite element analysis method of frame,the specific application of Hypermesh and ABAQUS in finite element analysis.And we also analyze the stiffness and strength of the load conditions.Lastly,we improved the structure which are under pressure.

Research results show that:In the plane of lifting mechanism,we exert forces of 100t.The material does not exceed the material limit.But the strengthening beam still can be installed to increase the stiffness and strength of the frame.

The characteristics of this paper:The characteristics of this paper are mainly based on the advantages of each software to choose software for finite element analysis,modeling through the powerful modeling fuction of CATIA,meshing generation through the powerful pretreatment software like Hypermesh,and by the powerful calculation ability of ABAQUS,the stiffness and strength of the constrained force are calculated.The finite element analysis are completed by these softwares.Then we carry through the optimization design.

Key Words:;Frame;CAD/CAE;Hypermesh;ABAQUS;Finite ElementAnalysis;Static Analysis

[资料来源:http://THINK58.com]

[版权所有:http://think58.com]

目录

第1章 绪论 1

1.1 研究背景和研究意义 1

1.2 研究目标 2

1.3 研究过程与方法 2

1.4 论文结构安排 2

第2章 Hypermesh前处理 3

2.1 模型导入与多余部件的处理 3

2.2 抽取中面与几何清理 4

2.3 网格划分与网格质量检测 5

第3章 车架的静态分析 7

3.1 静力分析基本理论 7

3.2 汽车车架刚度理论 7

3.2.1汽车车架弯曲刚度 7

3.2.2汽车车架扭转刚度 9

3.3 车架载荷分类 9

3.3.1静载荷 9

3.3.2动载荷 10

3.4车架剪力弯矩的计算 10

3.5车架工况分析 11

3.5.1满载弯曲工况 12

3.5.2满载扭转工况 16

3.5.3紧急制动工况 18

3.5本章小结 20

第4章 车架优化 21

4.1 优化概述 21

4.2 优化模型 21

4.3 优化结果 22

第5章 总结与展望 23

5.1 本文总结 23

5.2 前景展望 23

参考文献 25

致谢 26 [来源:http://think58.com]