飞剪机剪切机构设计(含CAD图)

以下是资料介绍,如需要完整的请充值下载.

1.无需注册登录,支付后按照提示操作即可获取该资料.

2.资料以网页介绍的为准,下载后不会有水印.资料仅供学习参考之用.

密 惠 保

1.无需注册登录,支付后按照提示操作即可获取该资料.

2.资料以网页介绍的为准,下载后不会有水印.资料仅供学习参考之用.

密 惠 保

资料介绍:

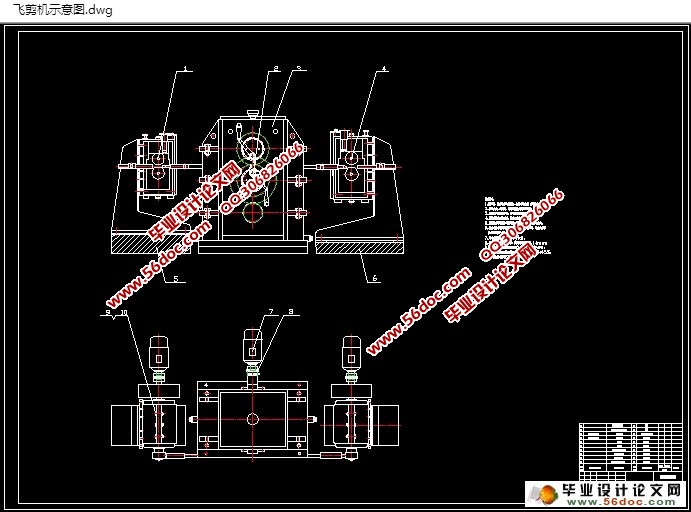

飞剪机剪切机构设计(含CAD图)(任务书,开题报告,外文翻译,论文设计说明书7800字,CAD图纸5张,答辩PPT)

内容摘要:本设计介绍了棒材飞剪机的功能要求及其剪切机构的性能参数。着重设计了飞剪机的剪切机构。设计根据加工原材要求主要设计飞剪机本体的剪切机构。

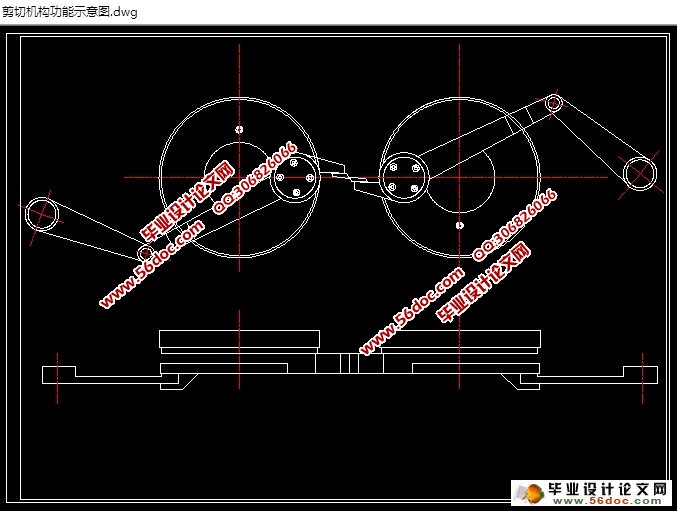

棒材飞剪机是现代轧钢生产线上的咽喉设备,它负责钢材的切头、切尾及定尺剪切。所以对飞剪机的设计研究具有十分重大的意义。本次设计由我们小组五个人共同完成一台飞剪机的设计。飞剪机的种类众多,根据加工要求选择合适的飞剪机类型十分重要,我们经过收集、学习有关飞剪机的资料进行分工合作,每人选择一个机构进行设计。我在本次设计中设计飞剪机的剪切机构,其主要功能是对轧件进行切头、去尾、事故碎断或将轧件剪切成定尺长度,功能的实现靠剪切机构为四连杆机构中曲柄摇杆式进行。

关键词:棒材、飞剪机、剪切机构、设计

Abstract:This design is introduced the function of the flying shear machine bar requirements and shearing mechanism performance parameters. Emphasize design the shearing mechanism of the flying shear machine. Design according to the major requirements raw material processing design the flying shear machine body shearing mechanism.

[来源:http://think58.com]

The bar flying shear machine is modern rolling line on the throat of the equipment, it is responsible for the steel cut head, cutting the end and scale shear. Therefore, the design of the flying shear is of great significance. The design consists of five people in our group together to complete the design of a flying shear. Many types of flying shear, according to the processing requirements to choose the right type of flying shear is very important, after collection, to learn about flying shear information division of labor, and each person to choose a body design. In this design of flying shear machine I design the shearing mechanism,the main function of rolled piece is in the head, to tail, accident broken off or will be rolled piece of cutting into scale length, the realization of the function of shearing mechanism on for four bar linkage of the crank rocker type.

Key words: bar, flying shearing machine, shearing mechanism, design.

[资料来源:http://think58.com]

[资料来源:www.THINK58.com]

目 录

内容摘要: 1

关键词: 1

Abstract: 1

1.飞剪机概述 2

1.1飞剪机简介 2

1.2剪切机构的工艺作用与分类 2

1.3剪切机构应满足的设计要求 3

2.剪切机构功能要求 3

2.1剪切机构功能 4

2.2剪切机构正常工作要求 4

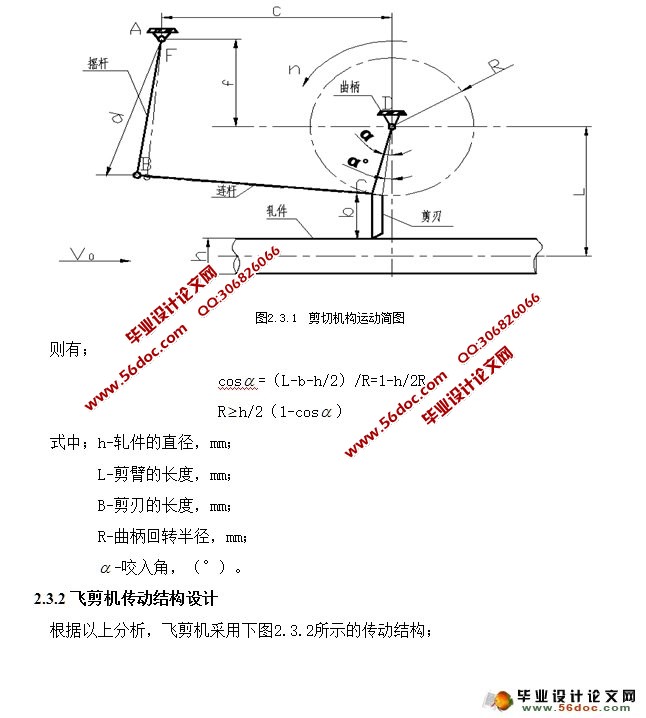

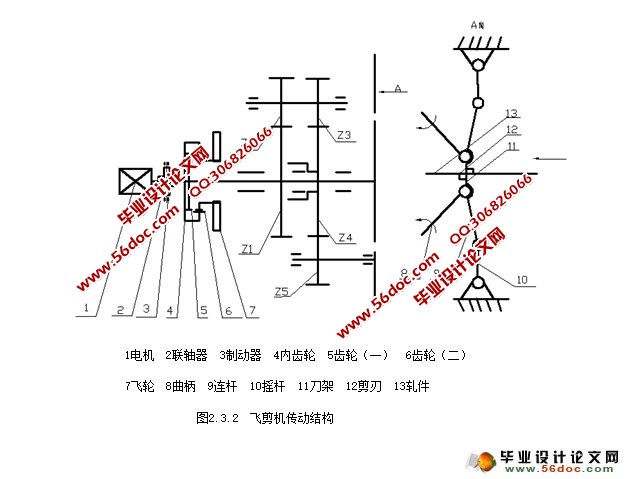

2.3剪切机构方案设计 4

2.4剪切机构运动学分析 7

3.剪切机构力学分析计算 9

3.1剪切机构受力分析 10

3.2剪切机构力的计算 11

3.3主轴剪切力矩和电机功率计算 14

4.剪刃垂直重叠量调整 16

结论 17

参考文献 18

致谢 19 [版权所有:http://think58.com]