铣床半轴夹具设计(含CAD零件装配图)

1.无需注册登录,支付后按照提示操作即可获取该资料.

2.资料以网页介绍的为准,下载后不会有水印.资料仅供学习参考之用.

密 惠 保

铣床半轴夹具设计(含CAD零件装配图)(任务书,文献综述,设计说明书11800字,CAD图纸4张)

摘要

夹具是现如今机械制造业应用的最广泛的加工工艺之一,因为它使得制造业的生产力有了显著地提升,科技的迅速向前发展使得夹具在现代机械制造业的地位愈发的重要,这其中铣床半轴夹具是在铣床上对轴进行操作时所使用的夹具。铣床半轴夹具的设计需要有很长的准备期。对于机械零件的精度,对轴的定位的影响很大。所以,这是一件重要并且麻烦的事,只有专业的技术人员才能熟练地操作。

在现代的产品生产流程过程当中,对于夹具的精度,强度,还有刚度的标准要求的高低,对夹具的使用得稳定性和可靠性大小,工作效率高低都会对产品的产生以及产品的加工质量有着很大的影响。所以,首先了解什么是夹具,夹具是用来干什么用的,明白了这些之后就应该开始着手于准备相应的夹具设计,经过一段周期的准备工作之后就得开始将工件装卡在所设计出的专用夹具之中开始检验定位,定位无误之后进行详细的误差具体分析,同时还得对加工精度做出保证,最后在计算出夹紧力的大小和夹紧位置和点数。现如今,机械制造工业已经从最初的一种品种、大量生产成功的转型到了今天很多品种、小批次、个性化制造,小批量多品种的生产,特别值得一提是在数控加工中得到了很好的应用,在成批生产中代替专用夹具率为35%左右,甚至是高达55%左右,所以传统夹具也已经不再适用现代的机械制造行业,但是夹具是任何工件的产生所不可或缺的一种加工工艺的设备,所以基于此发明了组合夹具这一种新型加工工艺设备,组合夹具设计是现代制造业夹具设计具有一定程度上的通用性,便于拆装,以应对不同工序,不同类型的机床,综上所述,组合夹具的设计是现代夹具制造业夹具设计的最佳选择。 [资料来源:http://THINK58.com]

与此同时,在现代的制造业当中夹具有着非常多的样式和类型以及它们都有着自己各自独特的应用的领域,所以现在要进行夹具的设计的话,大多数往往都是凭借有着长期而又丰富的工作经验的工作人员来当设计人员参与设计,所以不同的设计人员,不同的设计小组,因为有着不同的工作经验和阅历,往往设计出来的夹具也会有所不同,夹具的设计方案相比于之前在针对传统的夹具的设计当中所存在的一些问题与难题会一一的被现代制造业的技术的提升和工作人员素质与知识水平的提高所解决的。即便是万一出现报废的情况的话,也完全可以进行补救;技术层次薄弱的问题,提高企业的工艺装备的使用系数。

关键词:夹具设计;定位;夹紧力;组合夹具

Abstract

fixture design is one of the most widely used processing manufacturing now, and the science, technology development quickly make fixture in the status of modern mechanical manufacturing industry more and more important ,the time of the shaft to operate , clamp, milling machine axle shaft fixture looks be like simple, actually is not have so long time to prepare. For precision mechanical parts, is a great influence on axial positioning. So this is an important and troublesome, can only be skilled professional and technical personnel to operate.

in the modern production process, for the precision of the fixtures, intensity, and the standard requirements of high and low stiffness stability and reliability of the use of fixture, the low for the product and the product quality has impact .So, first to understand what is a fixture, it is used to do what, after I see these should start to prepare the corresponding fixture design, after in the design of special fixture on inspection location, locate and correct after

specific, while pledged to processing precision, finally calculate the clamping force and the clamping position and the size of the points. In the design , drilling is an important and troublesome thing, only skilled technicians can accurate hole drilling system. As a result, a large number of production or require parts must be interchangeable, the most effective drilling methods, is to make the recruitment mode, namely the drilling special fixture. Nowadays, mechanical manufacturing has from the original manufacturing , the success of mass production transformation by today, building modular fixture library by using Excel table-driven technology. Based on this, The virtual assembly of moduIar fixture was made for the typical process of one typicaI components.many varieties, small batch more varieties, especially in the machining got very good application, instead of special fixture in the batch production rate was about 35%, or even as high as 55%, so the traditional jig also is no longer applicable in modern manufacturing, any art artifacts produced by a kind of the processing equipment man , so than invented the modular fixture based on the this a new process ting technology equipment, so that what modular fixture design is a modern manufacturing fixture easy to tear open out fit, in reason response to tools about above all, the design of modular fixture is the best choice for modern fixture design.

In modern manufacturing industry, meanwhile, has very many style and types of jig and they all have their own independent field and scope of application, so now is for the design of fixture , most often with a long and rich work experience in personnel as design personnel to participate in the design, so the design of the different people, different design teams because of the different working with experience and experience, design the fixture will be different, fixture design, the method will be more flexible ,so, before the research in traditional fixture design of some problems and different difficult to do the manufacturing technology and staff quality and knowledge level of ascension to solve .even scrapped one thousand happen, also can remedy completely, moreover can also remedy completely, moreover can also solve the small and medium enterprise because of the lack of process equipment design and manufacture ability.

Key word: grip design; fixed position; clamp force; built-up jig

[资料来源:THINK58.com]

目 录

引言 1

第一章铣床半轴夹具的目的、意义和要求 2

1.1 铣床半轴夹具的设计目的 2

1.2 铣床半轴夹具的设计意义 2

1.3 铣床半轴夹具的设计要求 3

1.4 铣床夹具的应用及发展状况 4

第二章铣床半轴夹具的定位 6

2.1 描述铣床半轴夹具的定位 6

2.2 铣床半轴夹具的定位误差分析 9

第三章夹紧力的计算 11

3.1 夹紧方式及夹紧装置的作用 11

3.2 确定夹紧力时应考虑的计算系数 13

3.3 夹紧力的数值计算 15

3.4 夹紧点的位置与数目 17

第四章铣床半轴夹具的设计图 18

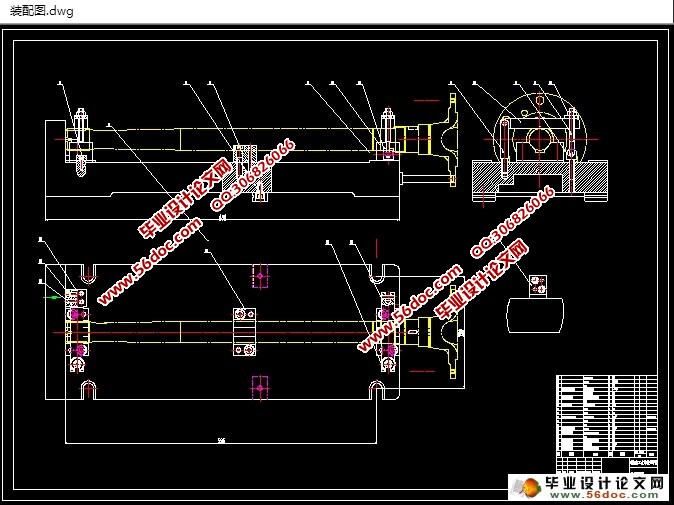

4.1 铣床半轴夹具的装配图及其简单说明 18

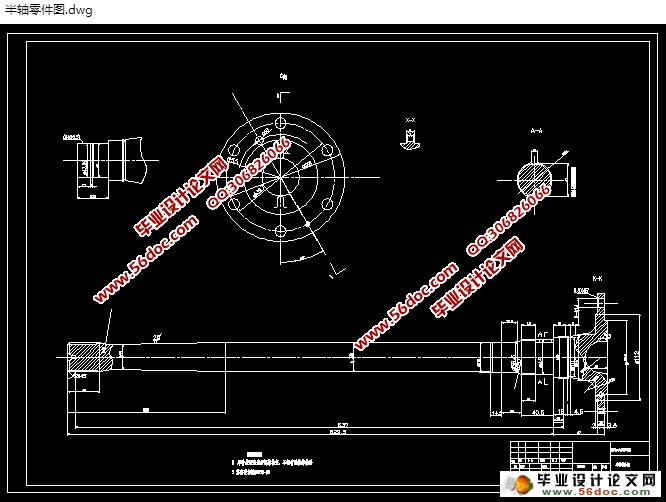

4.2 铣床半轴夹具V型零件图及说明 19

[资料来源:http://think58.com]

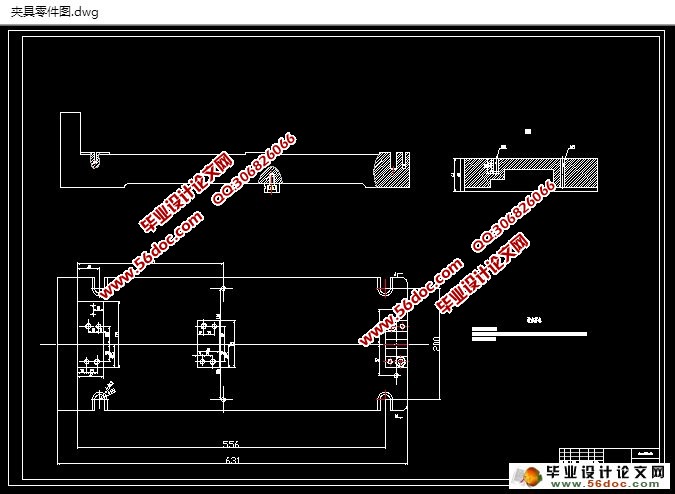

4.3 铣床半轴夹具图及说明 22

第五章结论 23

参考文献 24

致谢 25

[资料来源:www.THINK58.com]