污水处理装置电气控制系统设计(含CAD图)

1.无需注册登录,支付后按照提示操作即可获取该资料.

2.资料以网页介绍的为准,下载后不会有水印.资料仅供学习参考之用.

密 惠 保

污水处理装置电气控制系统设计(含CAD图)(开题报告,设计说明书18000字,CAD图纸4张)

摘要

由于存在一系列的水污染问题,我国经济进一步发展受到了很大的阻碍和约束。净化污水和对污水深度处理和再利用是解决水资源危机和通向健康水源的桥梁和途径。在我国,污水的净化和处理已经成为一项重要的政策,已是人类维护自然和人类可持续发展的一个重要举措。因此,污水处理装置的设计也成为了亟待发展的技术,它通常由动力系统、远程控制系统、就地操作系统以及电机、变频器等一系列电气系统和电气器件构成。

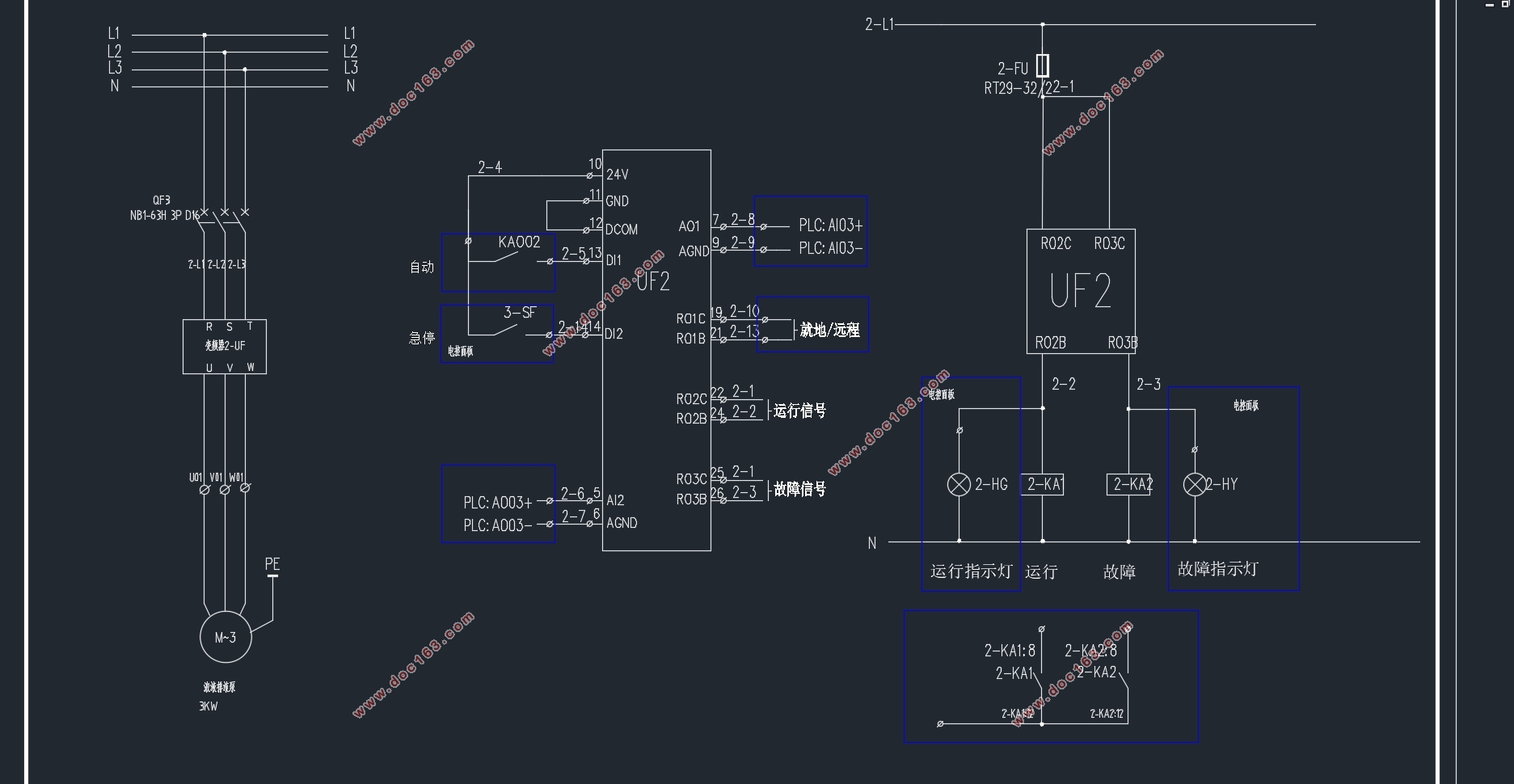

本文主要设计了一体化HPDM的热泵垃圾渗滤液的处理装置,以研究垃圾渗滤液的净化来实现污水处理。本文首先介绍了污水处理控制系统常用的工艺以及相关流程,对污水处理工艺做简要的介绍。然后,介绍了本次毕业设计所设计的一体化HPDM的热泵垃圾渗滤液的处理装置,该装置通过对垃圾渗滤液进行蒸发,将污水中的固体和盐类与水实现分离,从而达到净化污水的作用。本文还介绍了控制系统的硬件结构及设计、工作原理以及工作步骤,并对系统中水泵、阀门、变频器、水平蒸发管等一系列重要器件和设备进行了详细介绍。本文选择西门子S7—300系列PLC作为污水处理系统的电气控制系统的控制主机,通过给定电流、反馈电流,输入信号、输出信号,在电路中进行模拟信号传输来实现控制,以达到控制水泵的转速和电动阀门的开与关。除了设备选型,本文还详细介绍了供配电系统的设计、变频器控制电机电路的设计,以及电动阀门的远程控制电路的设计。另外,本文还对电气柜和控制柜的柜体设计做了简要的介绍。系统功率的计算,导线型号的选择以及其与设备之间的接线也是本次毕业设计的重点。

[资料来源:http://think58.com]

关键词:远程控制 就地操作 变频器 模拟信号 罗茨风机 S7-300PLC

Abstract

Due to a series of problems of water pollution, the further development of China's economy has been greatly restricted. Purification of sewage and waste water treatment and reuse is to solve the crisis of water resources and a bridge to the healthy water and way. In our country, purification and sewage treatment has become an important policy, is an important measure to maintain the sustainable development of human nature and human being. Therefore, the design sewage treatment device has become to be the development of the technology; it usually consists of a power system, remote control system, local operating system and motor, frequency converter and a series of electrical system and electrical devices.

Processing device this paper designed to pump integration HPDM garbage leachate of landfill leachate, the purification of sewage treatment to achieve. This paper first introduces the common process of sewage treatment control system and related processes, makes a brief introduction to the sewage treatment process. Then, introduces the processing device heat pump waste integrated HPDM the graduation design, the design of leachate, the device through the landfill leachate by evaporation, the sewage in the solid and salt and water separation, so as to achieve the effect of purifying wastewater. This paper introduces the working principle and working steps of hardware structure and design, control system, and the system of pumps, valves, converter, horizontal evaporator tubes and a series of important devices and equipment is introduced in detail. This paper choose Siemens S7 - 300 series PLC as the central control unit of electric control system of sewage treatment system, given by the current, the feedback current, input and output signal, signal, to realize the control of the analog signal transmission in the circuit, in order to control the rotation speed of the pump and an electric valve opening and closing. In addition to the selection of equipment, this paper also introduced the design of electric circuit design, power supply and distribution system design of inverter control, and remote control circuit of electric valve. In addition, this paper also cabinet design of electrical cabinet and control cabinet is briefly introduced. The calculation of system power, focus on the connection between the conductor type selection and its equipment is the graduation design.

[来源:http://www.think58.com]

Keywords: Electrical control, Remote control, Frequency converter, Analog signal, Roots blower, S7-300PLC.

主要电气设备选型及其工作原理

一体化HPDM热泵垃圾渗滤液污水处理装置的结构并不是很复杂,不同的结构对应不同的控制系统,因此需要根据不同的结构特点设计相应的控制系统。

一体化HPDM热泵垃圾渗滤液污水处理装置电气控制系统主要设计了四个基本模块,根据具体的设计要求,我们需要选择大量的电气设备。对于设备的选择,它们有着很高的要求。

[来源:http://www.think58.com]

[来源:http://www.think58.com]

目录

摘要 I

Abstract II

第一章 绪论 1

1.1 污水处理的国内外现状 1

1.2 课题的背景和设计的意义 3

第二章 垃圾渗滤液处理工艺的介绍 5

2.1 垃圾渗滤液处理常用的工艺方法 5

2.1.1 UASB厌氧处理工艺 5

2.1.2 SBR好氧处理工艺 5

2.1.3 氨吹脱工艺 6

2.1.4 膜法深度处理工艺 6

2.1.5 渗滤液蒸发处理 7

2.2 一体化HPDM热泵垃圾渗滤液处理装置及其特点 7

2.2.1 一体化HPDM热泵垃圾渗滤液处理装置所用的工艺 7

2.2.2 一体化HPDM垃圾渗滤液处理装置的特点 9

第三章 主要电气设备选型及其工作原理 10

3.1 变频器 11

3.2 断路器 15

3.3 Y型过滤器 19

3.4 罗茨风机 19

3.5 继电器 20

3.6 接触器 20

3.7 PLC的选型 21

3.8 设备选型的总清单 26

第四章 电气控制系统的设计 31

4.1 电路配线的设计 31

4.2 供配电系统的设计 32

4.2.1 电气柜的设计 32 [资料来源:www.THINK58.com]

4.2.2 主控柜的设计 37

4.3 水泵控制系统的设计 43

4.4 电动阀门控制系统的设计 47

4.5 PLC控制系统的设计 50

第五章 总结 53

参考文献 54

致谢 56

[资料来源:http://think58.com]