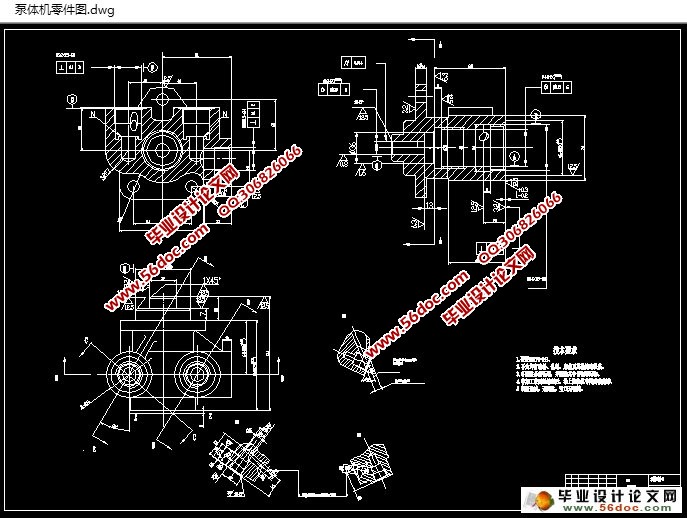

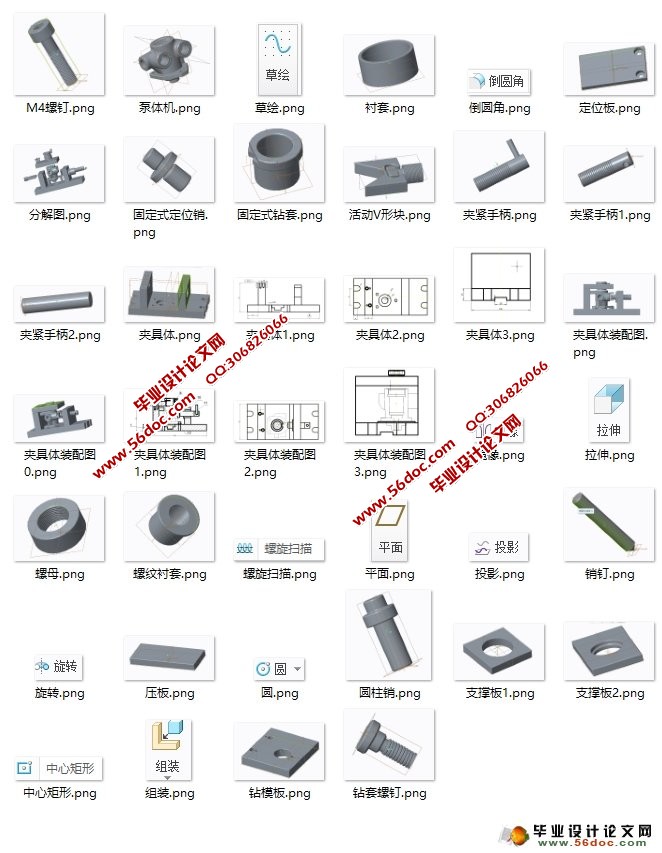

泵体的加工工艺及专用夹具设计(含CAD图,CREO三维图,工序工艺卡)

1.无需注册登录,支付后按照提示操作即可获取该资料.

2.资料以网页介绍的为准,下载后不会有水印.资料仅供学习参考之用.

密 惠 保

泵体的加工工艺及专用夹具设计(含CAD图,CREO三维图,工序工艺卡)(任务书,开题报告,外文翻译,论文说明书11200字,CAD图纸4张,CREO三维图,机械加工工艺卡,机械加工工序卡)

摘 要

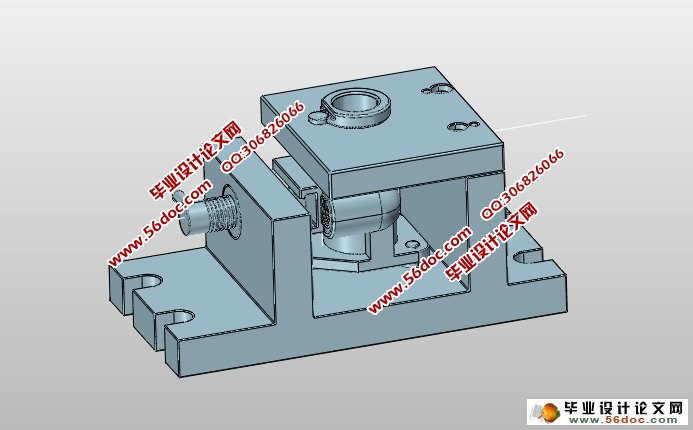

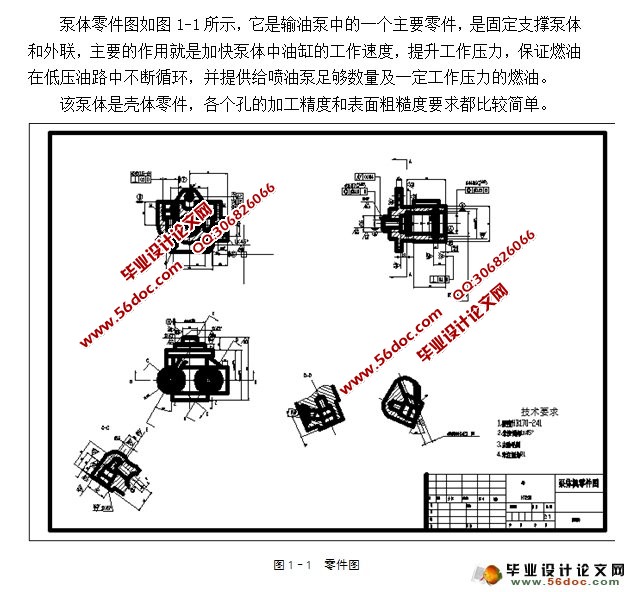

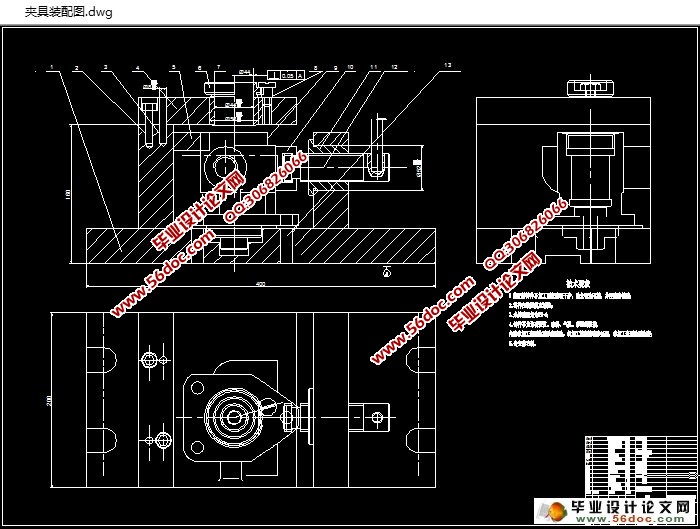

本次毕业设计课题是关于泵体总体工艺设计和其中一道工序的专用夹具设计。通过查阅各种相关书籍,分析壳体的结构及其功能。在对零件作工艺分析后,拟订两套工艺途径,经过分析、比较,选取此中一个更合理的加工工艺路线进行批量生产;并制订工艺规程的步骤,确定毛胚并且拟定工艺路线,确定各工序的工艺设备和辅助工具,确定各工序的加工余量并计算出工序尺寸及公差,最后确定切削用量及切削时间,填写工艺卡片和工序卡片。在制定机械加工工艺的基础上,设计出其中一道工序的专用夹具。依据零件的布局特性,选用一面两孔的定位方式及螺旋压板的夹紧方式。最后,绘制出夹具装配图及夹具零件图。

关键词:加工工艺;工序;定位;夹紧;钻床夹具

A Design About the Processing Technology of the pump body and the Special Jig

Abstract

This graduation project is about the overall process design of oil pump shell and the special fixture design of the process. Through access to various related books, analysis of the structure and function of the shell. After of parts for process analysis, draw up two sets of process route, through the analysis and comparison, select this in a more reasonable process route and batch production; And formulate process planning steps, determine moppet and develop process, determine the process of process equipment and auxiliary tools, determine the machining allowance for each process and calculate the process dimension and tolerance, finally determine the amount of cutting and cutting time. Fill in the process card and process card. On the basis of the development of mechanical processing technology, the design of a process of drilling jig. According to the characteristics of the parts of the layout, the use of a two hole positioning mode and the clamping way of the spiral plate. Finally, draw the assembly drawing and parts of the drilling jig.

Key words: processing technology; process; positioning; clamping; drilling fixture

[版权所有:http://think58.com]

[版权所有:http://think58.com]

[资料来源:http://THINK58.com]

目 录

摘要 .................................................... I

Abstract ............................................... II

绪论 .................................................... 1

第1章 泵体加工工艺规程设计 ..............................3

1.1 分析零件图 ....................................... 3

1.2 确定毛坯类型 ..................................... 3

1.3 机械加工工艺规程设计 ............................. 5

1.4 选择机床和工艺设备 ............................... 7

1.5 机械加工余量、毛坯尺寸的确定 .................... 10

1.6 确定切削用量和时间定额 .......................... 10

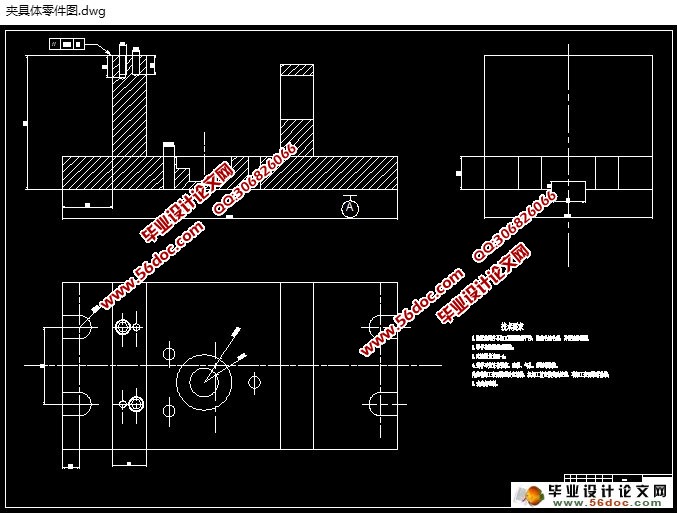

第2章专用夹具设计 ..................................... 23

2.1 设计任务 ........................................ 23

2.2 设计方法和步骤 .................................. 23

2.3 夹紧装置的设计 .................................. 23

[来源:http://think58.com]

2.4 定位误差分析..................................... 24

2.5 夹具体的确定 .................................... 25

2.6 绘制夹具装配图 .................................. 26

2.7 确定夹具的技术要求和公差配合 .................... 28

第3章夹具建模 ......................................... 29

3.1 夹具体造型 ...................................... 29

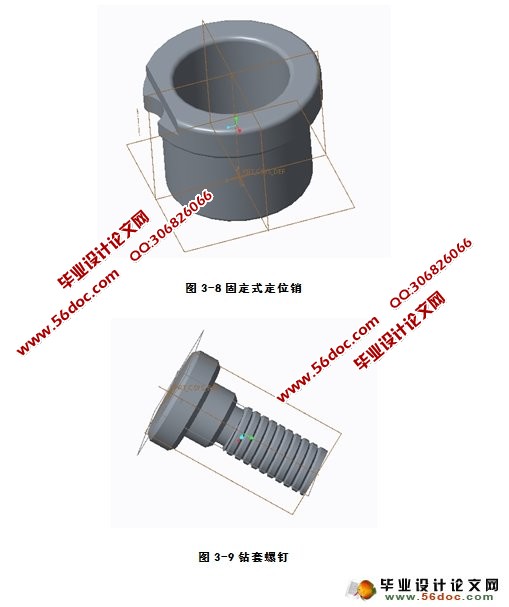

3.2 定位元件 ........................................ 29

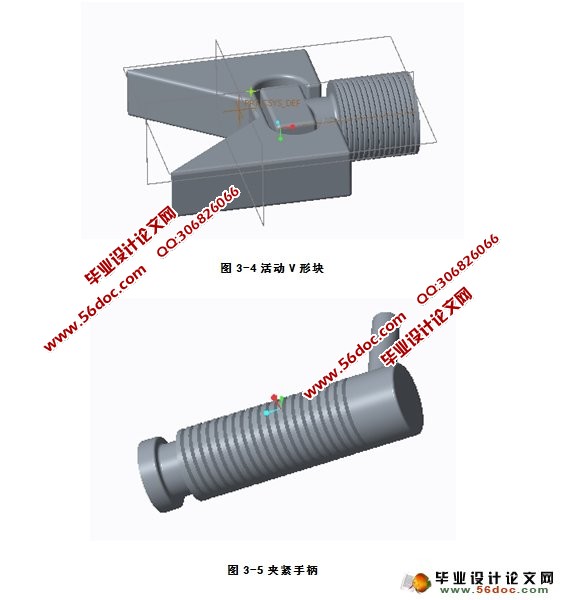

3.3 夹紧元件 ........................................ 30

3.4 导向元件 ........................................ 32

3.5 其他元件 ........................................ 34

3.6 夹具装配图 ...................................... 34

结论 ................................................... 36

参考文献 ............................................... 37

[资料来源:http://www.THINK58.com]

上一篇:曲轴箱箱盖缸孔端面螺纹底孔组合钻床及夹具设计(含CAD图)

下一篇:曲轴箱轴承孔端面螺纹底孔组合钻床及夹具设计(含CAD图)