减震支架加工工艺编制(实体加工仿真)及夹具设计

1.无需注册登录,支付后按照提示操作即可获取该资料.

2.资料以网页介绍的为准,下载后不会有水印.资料仅供学习参考之用.

密 惠 保

减震支架加工工艺编制(实体加工仿真)及夹具设计(任务书,开题报告,外文翻译,设计说明书12800字,cad图纸2张,工艺规程,仿真,答辩PPT)

摘要

减震器主要用来抑制弹簧吸震后反弹时的震荡及来自路面的冲击。在经过不平路面时,虽然吸震弹簧可以过滤路面的震动,但弹簧自身还会有往复运动,而减震器就是用来抑制这种弹簧跳跃的。支架起支撑作用的构架。减震支架保护内装的零部件不因外部的冲击震动导致其损坏。

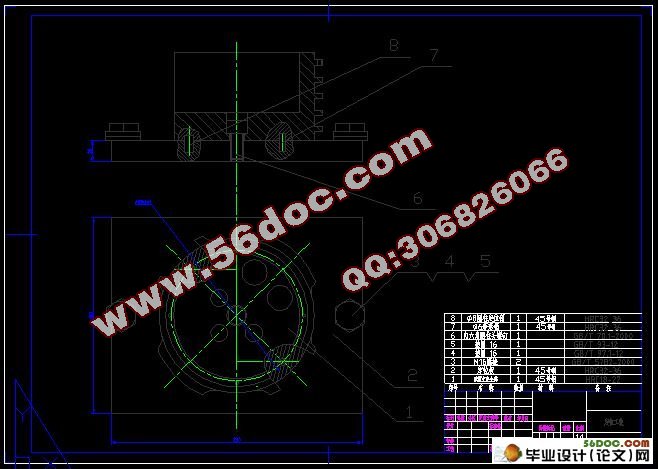

机械制造过程中用来固定加工对象,使之占有正确的位置,以接受施工或检测的装置,又称卡具。从广义上说,在工艺过程中的任何工序,用来迅速、方便、安全地安装工件的装置,都可称为夹具。在机床上加工工件时,为使工件的表面能达到图纸规定的尺寸、几何形状以及与其他表面的相互位置精度等技术要求 ,加工前必须将工件装好(定位)、夹牢(夹紧)。夹具通常由定位元件、夹紧装置 、对刀引导元件、分度装置、连接元件以及夹具体(夹具底座)等组成。

利用模型复现实际系统中发生的本质过程,并通过对系统模型的实验来研究存在的或设计中的系统,又称模拟。当所研究的系统造价昂贵、实验的危险性大或需要很长的时间才能了解系统参数变化所引起的后果时,仿真是一种特别有效的研究手段。仿真的重要工具是计算机。仿真与数值计算、求解方法的区别在于它首先是一种实验技术。仿真的过程包括建立仿真模型和进行仿真实验两个主要步骤。 [资料来源:http://THINK58.com]

关键词:减震 支架 夹具 仿真

ABSTRACT

Mainly used to suppress the vibration damper after a rebound during the spring and shock-absorbing impact from the road . After a rough road when , although shock-absorbing spring can filter the road shock , but there will be a reciprocating movement of the spring itself , and the damper spring is used to suppress such jumping . Bracket play a supportive role in the architecture . Built-in shock absorber bracket parts protection due to external shock and vibration without causing damage .

Mechanical manufacturing process for fixing the object , so that occupies the correct position to receive the detecting means or the construction , also known fixtures . Broadly speaking , any step in the process , used quickly , easily and safely install the device workpiece can be called a fixture. When the workpiece on the machine , in order to make the surface of the workpiece can reach the size of the drawing requirements , and the mutual position of the geometry precision technical requirements and other surfaces , the workpiece must be installed prior to processing ( positioning ) , clip prison ( clamping ) . Fixture usually consists of a positioning element , clamping device, the knife guide elements , indexing device , connecting elements and specific folder ( clamp base ) and other components. [来源:http://think58.com]

The nature of the model using the reproduction process occurs in the actual system and the model of the system through the experimental design to investigate the presence or system , also known as simulation. When the system under study is expensive , large or dangerous experiment takes a long time to understand the consequences caused by changes in system parameters , simulation is a particularly effective means of research . Computer simulation is an important tool . Simulation and numerical calculation, the difference between solving approach is that it is an experimental technique first . The simulation process including the establishment of a simulation model and simulation experiments of two main steps.

Keywords : shock bracket fixture simulator

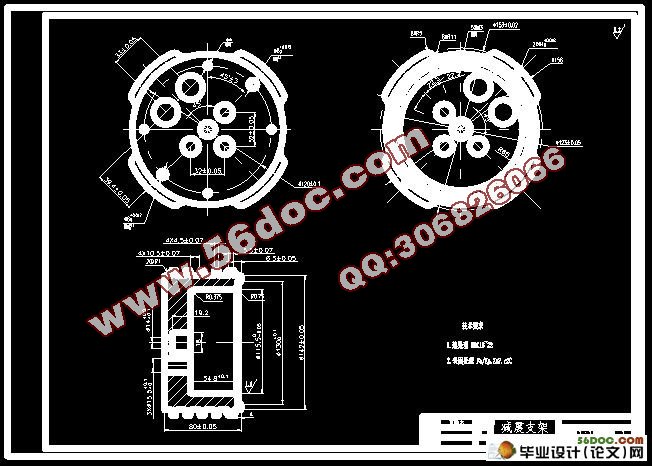

减震支架结构分析

如图2-1所示为减震支架的零件图。由图可知减震支架为一圆柱形壳体零件,减震支架是用来保护其内装的零部件不因外部的冲击、震动导致损坏。整体尺寸为直径Φ158高80,材质为45#钢。主要技术要求有热处理、表面处理和孔的位置精度。通过对零件图的仔细审读,该零件上表面分布有众多孔,其圆柱外表面分布均匀的槽,底部有型腔并有孔分布。由此可知该零件结构相对复杂,外形加工部位多,加工难度较大,在加工孔的过程中容易产生偏差,难以保证加工精度和表面质量。

[资料来源:http://www.THINK58.com]

2.3减震支架加工工艺分析

通过对减震支架零件的结构分析,现在对其加工工艺进行分析。

目 录

摘要 Ⅰ

ABSTRACT Ⅱ [版权所有:http://think58.com]

第一章 绪论 1

1.1 课题背景 1

1.2设计目的和意义 1

第二章 减震支架零件结构与工艺分析 3

2.1 机械加工工艺要求 3

2.2减震支架结构分析 4

2.3减震支架加工工艺分析 4

第三章 减震支架加工工艺路线 7

3.1减震支架加工工艺路线的拟定 7

第四章 减震支架配套夹具设计 13

4.1 机床夹具 13

4.2 减震支架夹具设计 15

第五章 MASTERCAM实体仿真 18

5.1 Mastercam简介 18

5.2减震支架加工仿真及编程过程 18

第六章 总结与展望 26

6.1总结 26

6.2展望 26

参考文献 27

致谢 28

毕业设计小结 29

[资料来源:www.THINK58.com]

上一篇:花键轴工艺及钻模设计

下一篇:连杆工艺及扩孔夹具设计