年产3000万粒α-淀粉酶-山楂提取物肠溶片生产工艺设计

1.无需注册登录,支付后按照提示操作即可获取该资料.

2.资料以网页介绍的为准,下载后不会有水印.资料仅供学习参考之用.

密 惠 保

年产3000万粒α-淀粉酶-山楂提取物肠溶片生产工艺设计(13800字)

摘 要:本设计是在查阅大量文献资料,并对国内外α-淀粉酶-山楂提取物肠溶片研究现状深入调研的基础上,依据实验室数据设计的。

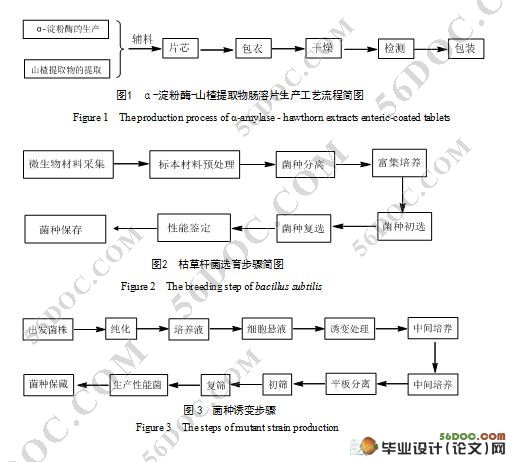

本设计采用枯草杆菌发酵法生产α-淀粉酶、50 %提取回流提取山楂提取物,再将α-淀粉酶、山楂提取物与辅料按一定量配比压片制成片芯,再经喷涂进行隔离层包衣,干燥后得到α-淀粉酶-山楂提取物肠溶片。根据设定的年产3000万粒α-淀粉酶-山楂提取物肠溶片,计算全年所需α-淀粉酶1800 Kg,山楂提取物1200 kg。然后根据目标,对α-淀粉酶的生产工艺、山楂提取物提取工艺、肠溶片制备工艺过程进行了物料衡算及能量衡算。得到了各个工艺过程中每个周期及全年原料的用量。

本设计根据设计目标,对主要设备进行选型计算,得出了发酵罐、反应釜、储存罐以及进料泵等关键设备的尺寸大小。

关键词:α-淀粉酶 山楂提取物 肠溶片 物料衡算 能量衡算

Production process design of 30 million pills α-amylase-hawthorn extracts coated tablets yield yearly

Abstract:In this design, through the consult massive literature material and deep investigation into the current research status of α-amylase-the hawthorn extracts coated tablets, The process flow is designed according to experimental data.

[资料来源:www.THINK58.com]

In this design, α-Amylase was produced by biological fermentation with bacillus subtitles, the hawthorn extracts was extracted directly by 50 % ethanol circumfluence,and then piece core of coated tablets were produced by pressing with α-amylase , the hawthorn extracts, trimmings. The piece core was coated by spraying. The product obtained after drying. 1800 Kg α-Amylase, 1200 Kg the hawthorn extracts were used in one year which is calculated with annual output of 30 million pills α-amylase- hawthorn extracts-coated tablets. Material-balance calculation and heat-balance calculation were introduced into production process of α-amylase and the hawthorn extracts. Through material-balance and heat-balance, amount of raw materials in per production cycle calculation and in full-year were obtained.

In this design, According to the design aim., we determine the general size of agitated fermenting tanks, reaction vessels, storage tanks etc, the selection.

Key words: α-Amylase The hawthorn extracts Coated tablets Material-balance calculation Heat-balance calculation [资料来源:www.THINK58.com]

本文在查阅大量文献资料的基础上,对国内外α-淀粉酶-山楂提取物肠溶片中α-淀粉酶生产工艺、山楂提取物提取工艺、肠溶片生产工艺的研究现状展开了深入的调研。以年产年产3000万粒α-淀粉酶-山楂提取物肠溶片为设计目标,对α-淀粉酶-山楂提取物肠溶片生产工艺进行了设计,主要完成以下内容。

一 淀粉酶发酵工艺流程进行了设计,对其工艺流程进行物料衡算、能量衡算,并对主要设备进行了选型计算,其中α-淀粉酶每年需要1800kg,对于喷射加热器加热需每年36849.96KJ热,蒸气用量为每年2180.2Kg,发酵热量为每年86994.3KJ。并选择0.2 m3的反应釜:公称直径为D内=500 mm,H筒=1000 mm,壁厚4 mm。

二 提取物提取工艺流程进行了设计,对其工艺流程进行物料衡算、能量衡算,并对主要设备进行了选型计算,其中山楂提取物每年需要1200 Kg,需要提供的热量为每年138693.605 KJ,需要蒸汽量为每年69.02 Kg。并选择0.65 m3的反应釜:公称直径为D内=800 mm,H筒=1600 mm,壁厚4 mm。选择Φ2200 mm×L9400 mm的12 m3的卧式乙醇存储槽。选择型号IS50-32-125型不锈钢磁力驱动泵:流量6.3 m3/h,扬程5 m。

三 工艺流程进行了设计,对其工艺流程进行物料衡算。 [资料来源:http://www.THINK58.com]

四 酶-山楂提取物肠溶片生产车间布置进行了总体规划。

[资料来源:http://think58.com]