基于单片机的三维车削力测量系统的设计(附电路图,元器件清单,程序清单)

1.无需注册登录,支付后按照提示操作即可获取该资料.

2.资料以网页介绍的为准,下载后不会有水印.资料仅供学习参考之用.

密 惠 保

基于单片机的三维车削力测量系统的设计(附电路图,元器件清单,程序清单)(任务书,开题报告,外文翻译,论文15000字,CAD图1张,元器件清单,程序清单)

摘要

车削过程中由工件作用在刀具上的切削抗力称为车削力。车削力作为监测加工状态的主要信息来源之一,是机械加工过程中最基本的物理参数之一。车削力直接决定着切削热的产生,并影响刀具磨损、破损、刀具耐用度、加工精度和已加工表面质量[1]。

在生产中,车削力又是计算切削功率,制定切削用量,监控切削状态,设计和使用机床 、刀具、夹具的必要依据。因此精确地测量车削力,对于选择理想的切削参数及合理的车削力是重要的。车削力的测量是研究和优化切削参数、改善和提高切削水平的重要途径和手段。目前的一些车削力测量结果还是通过示波器显示或坐标纸画出,不够准确和直观,而随着计算机和数字化的发展,这些检测装置和实验系统亟待改进。

本文从切削力产生原因入手,分析了切削力的合成分解及经验计算公式;阐述了八角环测力仪结构和传感电路原理;搭建了基于单片机的三维车削力测量系统。该系统适用于测量CA6140车削加工时的三维车削力,能够完成与上位机的通讯,能够完成测量数据的读取、存储。本文中主要通过软件仿真和实验验证方法,研究所提出技术方法的可行性与准确性。 [资料来源:http://THINK58.com]

关键词:车削力;力传感器;单片机;三维车削力的测量

Abstract

The cutting resistance acting on the tool by the component is called the turning force during the turning process. Turning force,as one of the main sources of information, is one of the most basic physical parameters to monitor the machining status in the machining process. The turning force directly determines the heat generated by the cutting and affects the tool wear, damage, tool durability, machining accuracy and machined surface quality [1].

In production, the turning force is the necessary basis for calculating the cutting power, setting the cutting amount, monitoring the cutting state, designing and using the machine tool, tool and fixture. Therefore,precise measurement of turning force, for the choice of the ideal cutting parameters and reasonable turning force,is important. The measurement of the turning force is an important way and means to study and optimize the cutting parameters, improve the cutting level. The results of some of the current turning force measurement or through the oscilloscope display or coordinate paper to draw are not accurate and intuitive. With the development of computer and digital technology, these detection devices and experimental systems need to be improved.

This paper starts from the causes of cutting force. Next to analyzes the synthetic decomposition and calculation formula of cutting force, expatiates the structure of octagonal ring dynamometer and the principle of sensing circuit. Finally, I built a three-dimensional turning force measurement system based on microprocessor. The system is suitable for measuring the three-dimensional turning force in the CA6140 turning process. It not only can complete the communication with the host computer, but also complete the measurement data to read, store. In this paper, I study the feasibility and accuracy of the method technical proposed by the methods of software simulation and experimental verification.

Key words: turning force; force sensor; microprocessor; three-dimensional turning force measurement

[资料来源:http://www.THINK58.com]

目录

第一章 绪论 1

1.1研究的目的及意义 1

1.2切削力的分解 1

1.3国内外的研究现状 2

1.3.1车削加工中的加工信息 2

1.3.2车削力的测量 3

第二章 三维车削力总体方案设计 6

2.1 三维车削力测量系统的功能 6

2.2设计方案比较与论证 6

2.2.1方案一 6

2.2.2方案二 7

2.2.3方案选择 7

第三章 力传感器 8

3.1传感器的构成 8

3.2材料选用 9

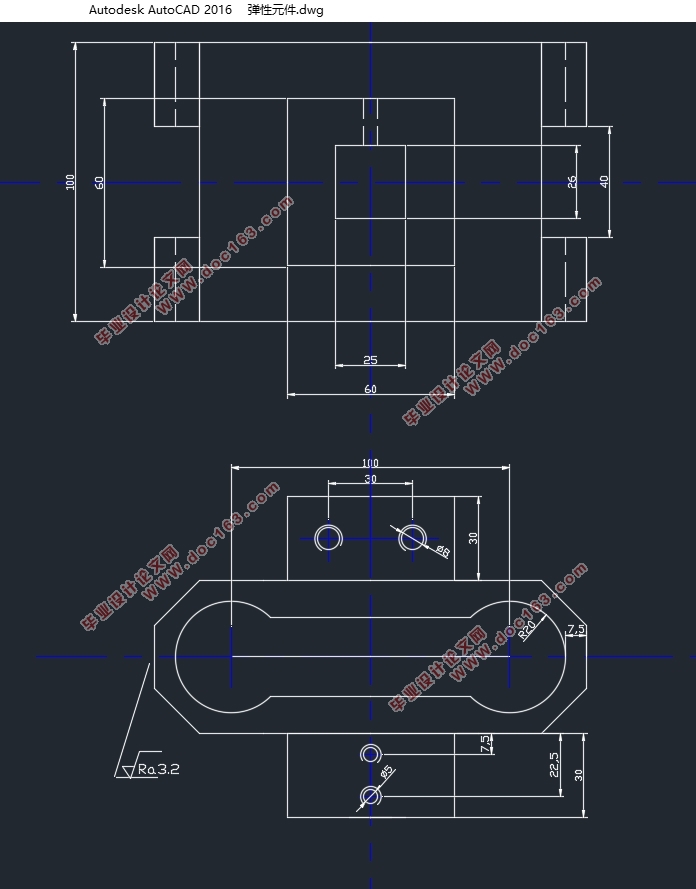

3.1.1 弹性元件 9

3.1.2应变片的选择 9

3.2弹性元件的设计 10

3.2.1弹性元件力学特性分析 10

3.2.2测力仪尺寸的设计计算 12

3.2.3测力仪强度校核 20

第四章 测力仪的测量电路 22

4.1电桥电路 22

4.2放大、滤波电路 24

4.3峰值检波电路 26

4.4计算测力仪的灵敏度 27

第五章 电路板的设计 28

5.1单片机最小系统 28

5.2 A/D转换模块 28

第六章 软件设计 30

6.1单片机程序设计 30

6.2 Labview程序设计 31

第七章 实验演示 34

7.1实物展示 34

7.2结果展示 34

第八章 总结 36

参考文献 37

附录 39

附录A:测力仪设计图纸 39

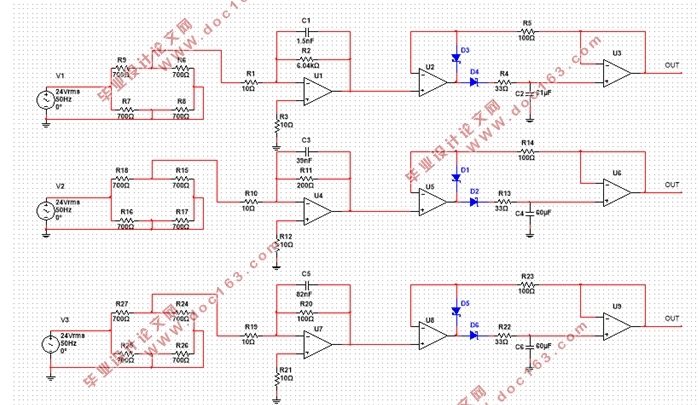

附录B:仿真电路图 40

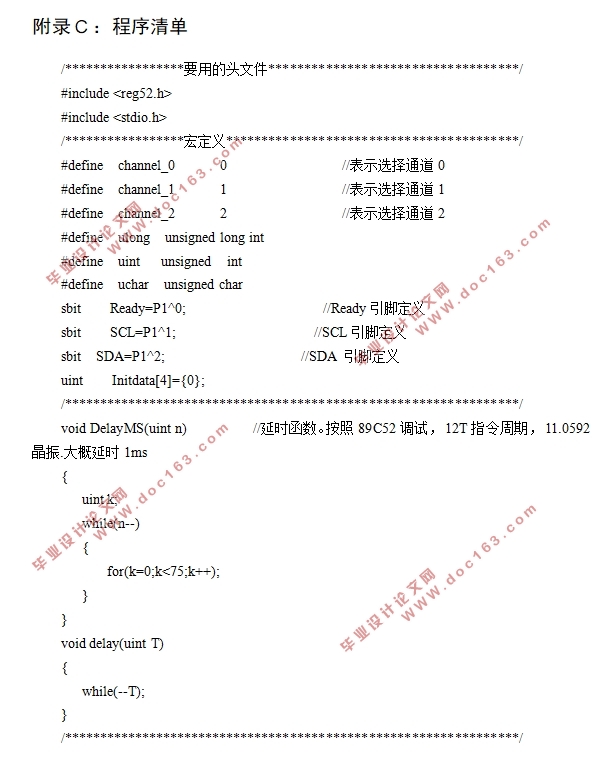

附录C:程序清单 41

附录D:元器件清单 50

致谢 51 [版权所有:http://think58.com]

上一篇:基于单片机的家庭环境监测系统设计

下一篇:基于单片机的二维钻削力测量系统设计(附元器件清单,程序清单)