多功能开瓶器冲压工艺及模具设计

1.无需注册登录,支付后按照提示操作即可获取该资料.

2.资料以网页介绍的为准,下载后不会有水印.资料仅供学习参考之用.

密 惠 保

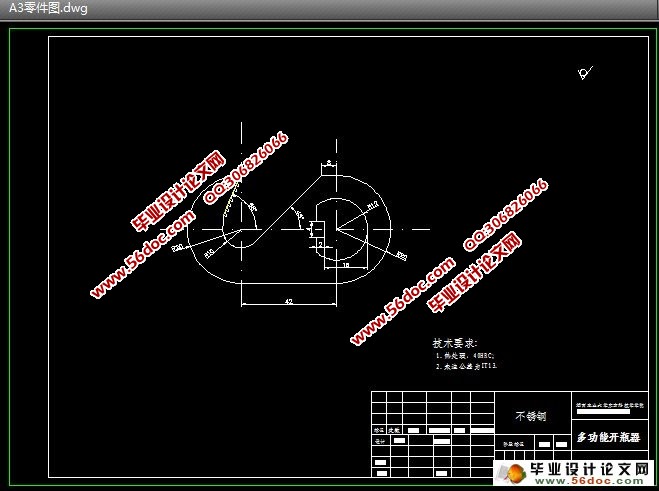

多功能开瓶器冲压工艺及模具设计(任务书,开题报告,论文说明书11500字,CAD图9张)

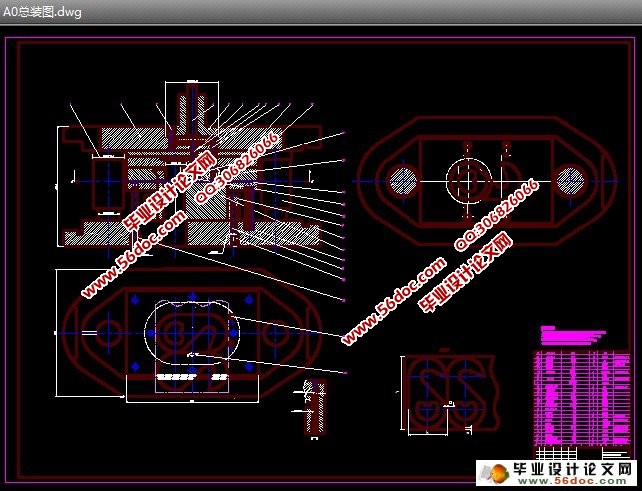

摘 要:本设计主要阐述了一种多功能开瓶器冲压模具的主要设计过程,主要原理是利用凸、凹模进行冲裁加工出目标零件。主要目的是设计多功能开瓶器冲孔落料成形复合模。文中主要分析了冲裁件的工艺性和排样方式。对冲裁过程中的工艺力以及压力中心进行了计算和分析,并对冲裁模的刃口尺寸进行的计算。对冲裁件的模具结构进行设计和计算,并同时对模具制造中的各个主要的零件结构尺寸进行了计算,根据资料选取合适的零件以保证模具的制造。对此模具绘制装配图、并对重要非标准间进行零件图绘制。

关键词:模具;冲孔;落料;凹模;凸模

The Design of Multifunctional Corkscrew Punch Technology and Mould

Abstract: This design mainly expounds a kind of multi-functional corkscrew stamping mould main design process, the main principle is to use convex, concave die cutting processing for the target parts. The main purpose is to design multi-function corkscrew punching blanking forming composite die. This paper mainly the blanking pieces of technology and layout mode. In the process of cutting force hedge process and pressure center has been calculated and analyzed, and hedge die size of the blade of calculations. The structure of the die cutting a hedge design and calculation, and at the same time for each of the mould manufacturing main parts structure size is calculated, according to the material to select the suitable parts to ensure the mould manufacturing. This figure, and drawing equipment mould of important the standard parts chart drawing.

[来源:http://think58.com]

Keywords: Mould; Punching; Dropping material; Concave die; The punch

[资料来源:THINK58.com]

[版权所有:http://think58.com]

目 录

摘要………………………………………………………………………………………………1

关键词…………………………………………………………………………………………1

1 前言………………………………………………………………………………………2

2 设计任务与分析…………………………………………………………………………4 [资料来源:http://think58.com]

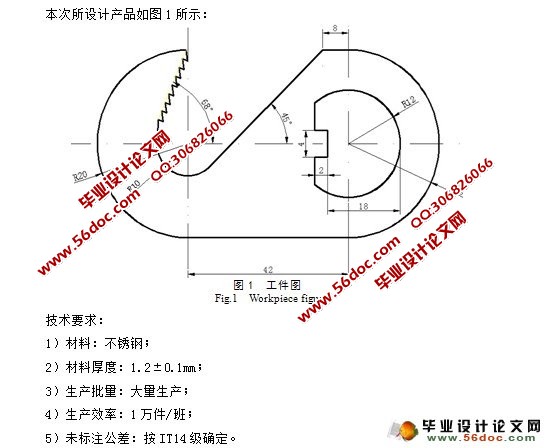

2.1 设计任务…………………………………………………………………………4

2.2 零件的工艺性分析………………………………………………………………4

3 零件工艺计算………………………………………………………………………………4

3.1 排样计算…………………………………………………………………………5

3.2 冲裁工艺力计算…………………………………………………………………6

3.2.1 周长的计算………………………………………………………………6

3.2.2 落料力……………………………………………………………………6

3.2.3 冲孔力……………………………………………………………………6

3.2.4 落料时卸料力……………………………………………………………6

3.2.5 冲孔时推件力……………………………………………………………7

3.2.6 冲裁时总工艺力…………………………………………………………7

3.3 确定模具的压力中心……………………………………………………………7

4 凸凹模的设计……………………………………………………………………………8 [资料来源:http://think58.com]

4.1 凸、凹模刃口尺寸计算…………………………………………………………8

4.2 凸模、凹模、凸凹模的结构设计………………………………………………10

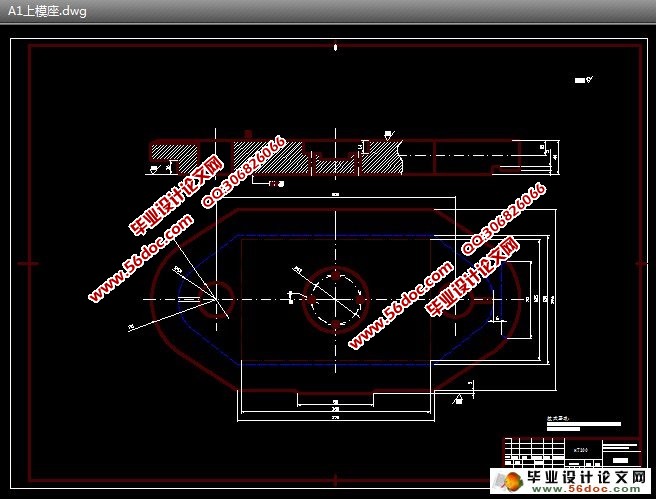

5 模具的总体设计及主要零部件…………………………………………………………11

5.1 上模座、下模座的设计…………………………………………………………11

5.2 导柱、导套………………………………………………………………………13 [资料来源:http://think58.com]

5.3 模柄………………………………………………………………………………15

5.4 凸模固定板………………………………………………………………………16

5.5 垫板………………………………………………………………………………17

5.6 螺钉与销钉………………………………………………………………………17 [资料来源:http://www.THINK58.com]

5.7 卸料版……………………………………………………………………………18

5.8 弹性元件的设计……………………………………………………………………18

5.9 模具总图…………………………………………………………………………19

5.10 冲压设备的选择…………………………………………………………………20 [资料来源:http://think58.com]

5.11 凸模的长度及校核……………………………………………………………21

5.12 冲压设备校核…………………………………………………………………21

6 冲压模具零件加工工艺的编制…………………………………………………………22

6.1 凹模加工工艺过程………………………………………………………………22

6.2 凸模加工工艺过程………………………………………………………………22

[来源:http://www.think58.com]

6.3 卸料版加工工艺过程……………………………………………………………23

6.4 凸模固定板加工工艺过程………………………………………………………23

6.5 上模座加工工艺过程……………………………………………………………24

6.6 下模座加工工艺设计……………………………………………………………24

6.7 磨齿………………………………………………………………………………25

[资料来源:THINK58.com]

7 总结…………………………………………………………………………………………25

参考文献……………………………………………………………………………………26

致谢……………………………………………………………………………………………27

附录…………………………………………………………………………………………27 [资料来源:http://think58.com]

上一篇:手机后盖注射模工艺及模具设计