集成式液动轮一体化设计(含CAD零件图装配图)

1.无需注册登录,支付后按照提示操作即可获取该资料.

2.资料以网页介绍的为准,下载后不会有水印.资料仅供学习参考之用.

密 惠 保

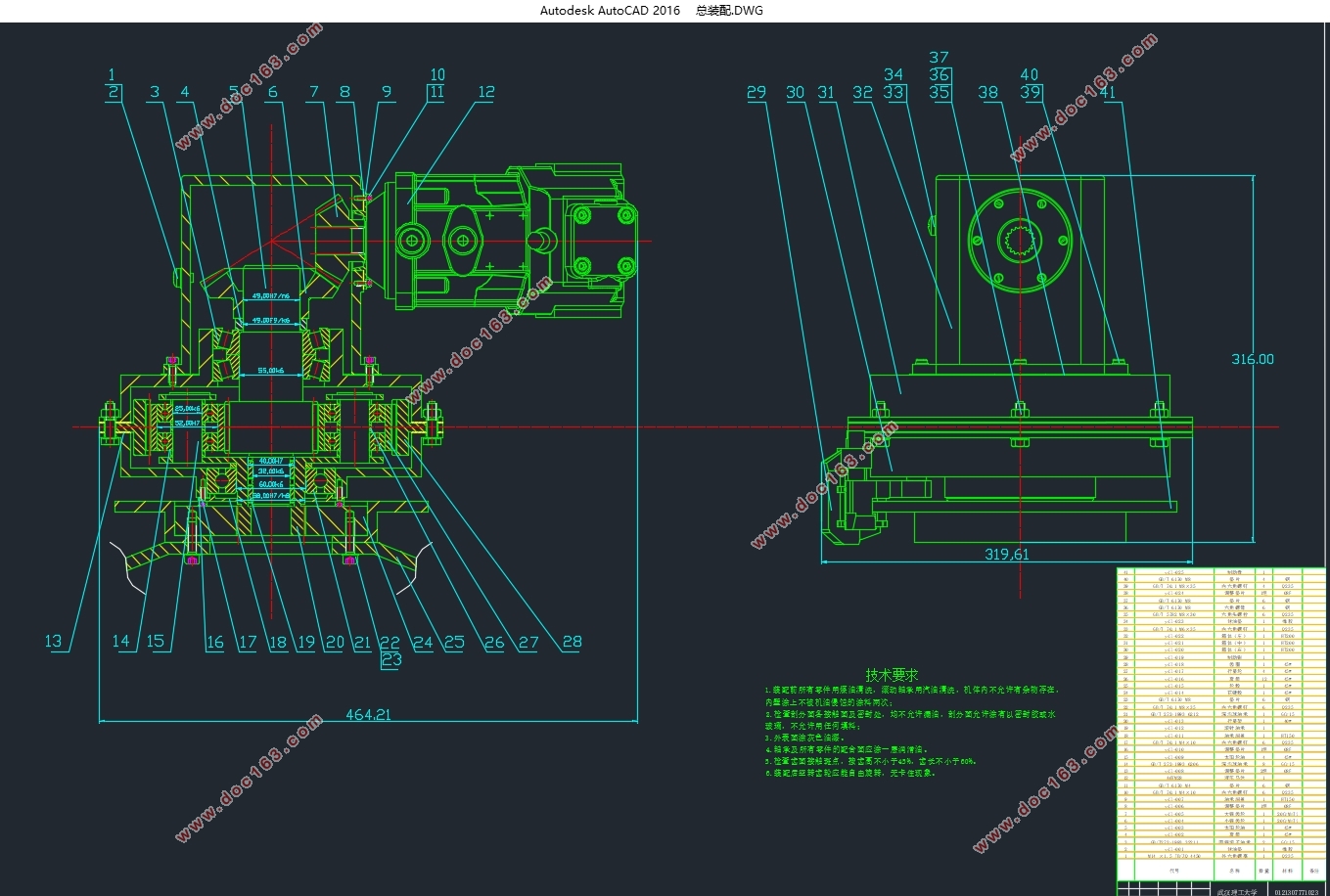

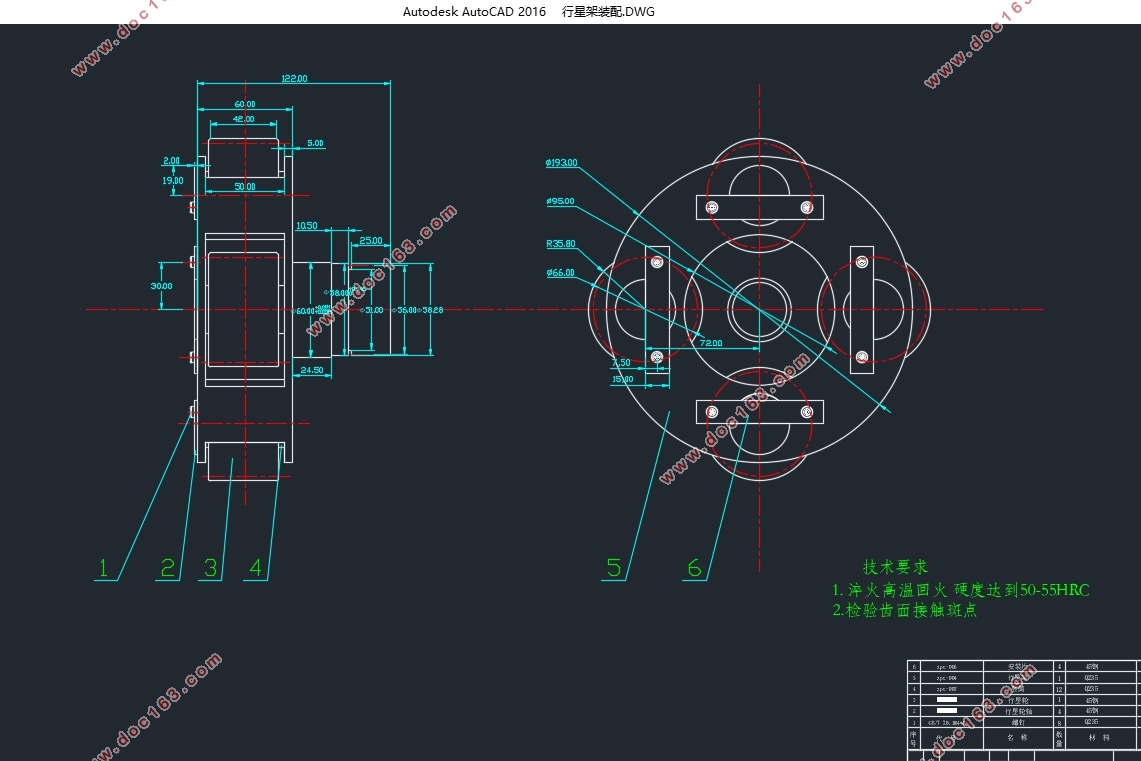

集成式液动轮一体化设计(含CAD零件图装配图)(任务书,开题报告,文献摘要,外文翻译,论文说明书13000字,CAD图5张)

摘要

军用越野车对动力装置要求日益增高,采用液压马达驱动可以有效的提高车辆的动力性和通过性。将马达、减速器和制动器集成在轮毂中,设计出动力性强于轮毂电机的集成式液动轮,完全改变了传统车辆的传动结构,增加了车内空间。液动轮的使用可以较好的提高整车的性能,增强作战能力。本文阐述了液压驱动的基本原理和优点,液动轮的设计流程,选定了液压马达的类型和布置形式。进行了整体的方案设计、配齿计算和关键部件的校核并进行了相关零件的结构设计。经过绘制二维图纸对比不同方案的优缺点后,确定了整体方案,并绘制三维图进行装配流程的设计以及干涉排查。最终基于北京理工大学“薪火摇臂无人平台”完成了集成式液动轮一体化的设计。

关键词: 轮毂电机,液压马达,集成设计

Abstract

As military off-road vehicles place increasingly greater demands on vehicle power plants, employing hydraulic motors can effectively improve vehicle dynamic performance and trafficability. This thesis integrates motor, speed reducer and brake into the wheel hub, designs an integrated hydraulic power wheel with better dynamic performance than in-wheel motor, differing completely from traditional vehicles in terms of transmission device, and saving room for the vehicle. Hydraulic wheel can improve vehicle performance and strengthen its abilities in the battlefield. This thesis elaborates the basic principles and advantages of a hydraulic motor, introduces the designing process of a hydraulic wheel, and determines the type of hydraulic motor and its detailed design. The thesis makes an overall design, calculates gear tooth parameter, checks key accessories and forms physical design of certain accessories. After drafting plans and comparing the advantages and disadvantages between two designs, an overall design is decided and a graphic model is established, with assembly process well designed and interference ruled out. Finally, based on the “Xinhuo” rockers unmanned vehicle, the design of an integrated hydraulic power wheel is completed. [来源:http://think58.com]

Key words: wheel hub motor; hydraulic motor; integrated design

整车参数

本文所研究的集成式液动轮摇臂悬架轮式无人平台,车辆主要参数如下。

表2.1 整车主要参数

基本参数 设计值

驱动形式 6×4

整车整备质量 3.5t

整车尺寸 4.2×2.2×1.1m

最高车速 120km/h

车轮半径 0.625m

最大爬坡度 35°

空气阻力系数 0.8

滚阻系数 0.15

机械传动效率 0.7

[资料来源:THINK58.com]

目录

1. 绪论 1

1.1发展水平及趋势 1

1.2液动轮主要优点 1

1.3国内外技术对比 2

1.4课题背景和主要工作 2

1.5本章小结 4

2. 系统参数匹配及马达选型 5 [资料来源:http://THINK58.com]

2.1整车参数与计算 5

2.1.1整车参数 5

2.1.2整车功率计算 5

2.1.3布置形式 6

2.2液压马达选型 8

2.3本章小节 9

3. 机械装置设计 10

3.1整体传动设计 10

3.2锥齿轮设计 11

3.3行星齿轮设计 12

3.4太阳轮轴设计 13

3.5行星轮轴 14

3.6行星架设计 14

3.7轴承端盖 15

3.8箱体设计 16

3.9减速器的润滑 17

3.9.1齿轮的润滑 17

3.9.2滚动轴承的润滑 17

3.10本章小结 17

4.主要零件的校核与装配 19

4.1轴的强度校核 19

4.1.1受力分析和计算载荷 19

4.1.2轴的校核 20

4.2轴承的选取及校核 22

[资料来源:THINK58.com]

4.3键的校核 22

4.3.1平键的选取和校核 22

4.3.2花键的校核 23

4.4机械零件的装配 23

4.4.1装配流程 23

4.4.2干涉检查 24

4.5本章小结 25

5.总结与展望 26

致谢 27

参考文献 28

[资料来源:http://www.THINK58.com]

上一篇:本田CRV车制动系统设计(含CAD零件图装配图,SolidWorks三维图)

下一篇:重型牵引车车架的总体设计(含CAD零件图装配图,CATIA三维图)