基于单片机的工频电压有效值测量及显示系统设计

1.无需注册登录,支付后按照提示操作即可获取该资料.

2.资料以网页介绍的为准,下载后不会有水印.资料仅供学习参考之用.

密 惠 保

基于单片机的工频电压有效值测量及显示系统设计(任务书,开题报告,外文翻译,论文12000字,程序清单,电源仿真)

摘要

无论是在实际生产还是现实生活中,工频电都扮演了重要角色,而工频电有多个参数可供测量。在实际测量中,有效值是应用最为普遍的参数,因为它反映了一个电压所蕴含的能量。此次采用单片机的方式来进行测量,以数字化的方式测量工频电压有效值,并通过LCD系统显示。大大增加了测量的范围,提高了测量的精度,测量得更快,使得测量更加方便而准确。本文围绕基于单片机的电压有效值测量及显示系统,介绍了测量的原理及具体实现方案;根据实际设计了电压信号处理电路,阐明其设计原理并对其主要功能做详细解释;接着说明了A/D转换器的工作方式;阐明了单片机对有效值计算原理;并对部分具体功能的代码做出了简要说明。

关键字:单片机,工频电压,有效值测量

ABSTRACT

Whether in actual production or in real life, power frequency electricity plays an important role, and power frequency power has multiple parameters for measurement. In actual measurements, the rms value is the most commonly used parameter because it reflects the energy contained in a voltage. This time, the measurement is carried out by means of a single-chip microcomputer, and the effective value of the power frequency voltage is measured digitally and displayed by the LCD system. The measurement range is greatly increased, the measurement accuracy is improved, and the measurement is faster, making the measurement more convenient and accurate. This paper focuses on the voltage RMS measurement and display system based on single-chip microcomputer, introduces the principle of measurement and the specific implementation scheme; according to the actual design of the voltage signal processing circuit, clarifies its design principle and explains its main functions in detail; then explains A The working mode of the /D converter; clarifies the principle of the rms calculation of the single-chip microcomputer; and gives a brief description of the code of some specific functions. [资料来源:THINK58.com]

Keywords: single chip, power frequency voltage, RMS measurement

[资料来源:www.THINK58.com]

目录

第1章 绪论 1

1.1目的及意义 1

第2章 工频电压有效值测量原理及方法 3

2.1 工频电简介 3

2.2工频电压有效值的测量方案与比较 4

2.3工频电压有效值测量原理 5 [来源:http://think58.com]

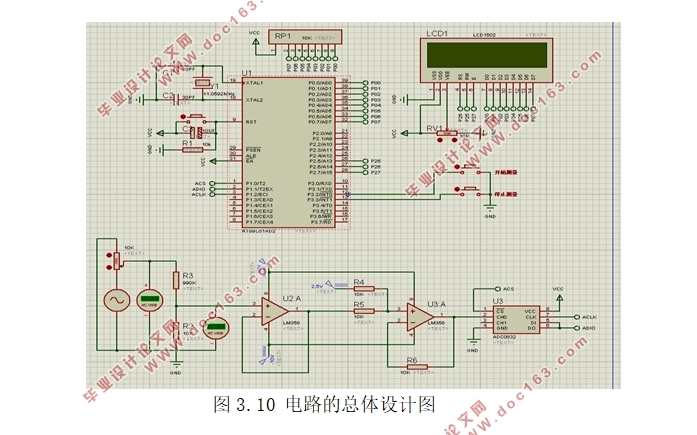

第3章 工频电压有效值测量硬件电路的设计 6

3.1电源模块的设计 6

3.2 工频电压信号采集与处理模块 7

3.3 ADC0832介绍 10

3.4 单片机电路简介 12

3.5按键模块 13

3.6显示模块 14

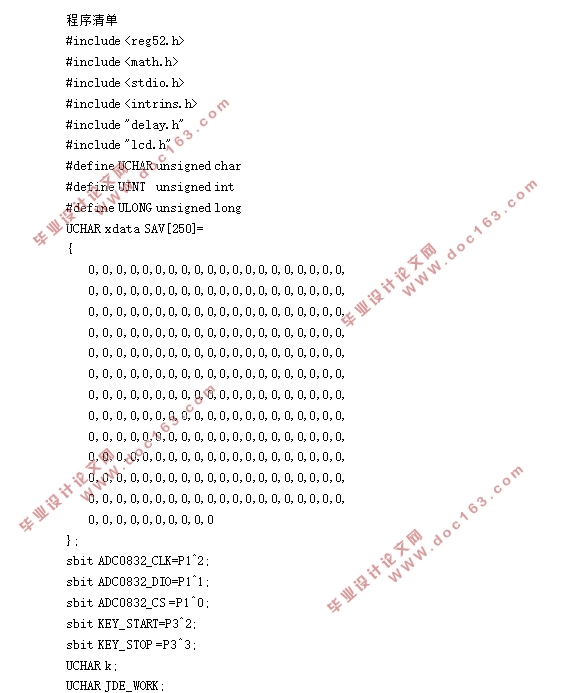

第4章 工频电压有效值测量软件部分设计 16

4.1 工频电压有效值测量流程 16

4.2 A/D转换流程图 17

4.3 定时器部分设计 18

4.4 工频电压有效值的计算 20

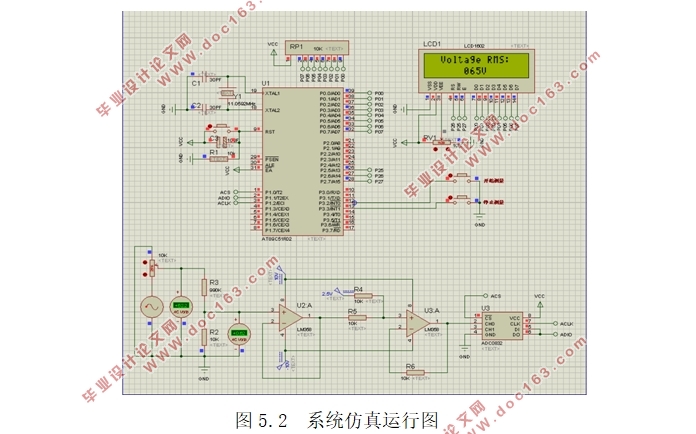

第5章 系统调试与误差分析 21

第六章 总结与展望 23

致谢 24

参考文献 25

附录 26